Hi all,

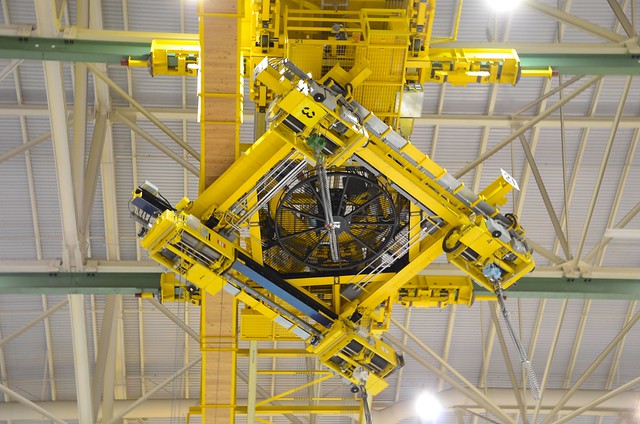

Have to use 2 sets of VFDs. Each set caters to 4 nos of 3.7KW Induction motors. These 8 motors are situated at the 4 corners of a square platform that will be used to lift 10,000Kg material. The platform moves in the vertical direction thru a rack pinion arrangement at all 4 corners of the platform. As shown in the diagram attached, M1,2,3&4 will be driven by one 20KW Yaskawa A1000 VFD and M5,6,7&8 will be driven by another 20KW Yaskawa A1000 VFD. The brakes on the motors will be operated by combined Torque proving relay.

I need suggestions as to how would be the best mode of operation of such a system

Thanks

Have to use 2 sets of VFDs. Each set caters to 4 nos of 3.7KW Induction motors. These 8 motors are situated at the 4 corners of a square platform that will be used to lift 10,000Kg material. The platform moves in the vertical direction thru a rack pinion arrangement at all 4 corners of the platform. As shown in the diagram attached, M1,2,3&4 will be driven by one 20KW Yaskawa A1000 VFD and M5,6,7&8 will be driven by another 20KW Yaskawa A1000 VFD. The brakes on the motors will be operated by combined Torque proving relay.

I need suggestions as to how would be the best mode of operation of such a system

Thanks