Eager Beaver

Member

Hello friends,

I’ve recently started learning about PLCs and HMIs after I acquired a Wago 750-871 with one digital input card and two digital output cards attached along with a Maple Systems HMI5080T.

I have also downloaded CoDeSys 2.3 with the relevant Target Support Package and am using EasyBuilder 5000 to program my Maple Systems/Weintek HMI.

Please forgive me if my questions are too simple but I have spent a week reading the Wago manual and have also been playing around with creating bit lamps but I just cannot seem to figure out what the correlation is between the two platforms’ addressing schemes.

I know that Wago uses the IEC 61131 format of %QX0.0 but everything in EasyBuilder refers to addresses such as 0x0000 or 3x0000 or 4x0000.

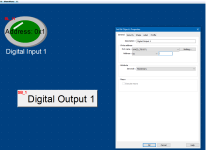

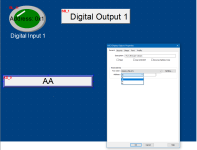

I have figured out that reading address 0x00001 will indicate the input status of port 1 on my 8-port digital input card and was successful in getting a lamp to “light” on the HMI when I applied 24V to it.

What I am not able to figure out is how to enable a digital output. I have two 8-port digital output cards which are just after the digital input card in the set. I have tried to setup buttons on the HMI which write to all kinds of addresses but nothing seems to work.

My background has been with microcontrollers such as Arduino and Teensy so I am still learning but would really appreciate any hints you can provide.

Thank you.

I’ve recently started learning about PLCs and HMIs after I acquired a Wago 750-871 with one digital input card and two digital output cards attached along with a Maple Systems HMI5080T.

I have also downloaded CoDeSys 2.3 with the relevant Target Support Package and am using EasyBuilder 5000 to program my Maple Systems/Weintek HMI.

Please forgive me if my questions are too simple but I have spent a week reading the Wago manual and have also been playing around with creating bit lamps but I just cannot seem to figure out what the correlation is between the two platforms’ addressing schemes.

I know that Wago uses the IEC 61131 format of %QX0.0 but everything in EasyBuilder refers to addresses such as 0x0000 or 3x0000 or 4x0000.

I have figured out that reading address 0x00001 will indicate the input status of port 1 on my 8-port digital input card and was successful in getting a lamp to “light” on the HMI when I applied 24V to it.

What I am not able to figure out is how to enable a digital output. I have two 8-port digital output cards which are just after the digital input card in the set. I have tried to setup buttons on the HMI which write to all kinds of addresses but nothing seems to work.

My background has been with microcontrollers such as Arduino and Teensy so I am still learning but would really appreciate any hints you can provide.

Thank you.