so im not sure if what i have come up with is the proper way to accomplish what im looking to do so hopefully someone here can straighten me out.

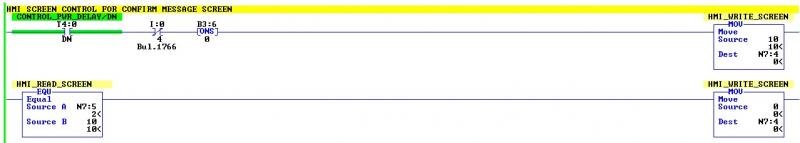

attached screenshot.

what im trying to do, using a ML1400 and a Panelview 800, is use a prox switch to trigger a screen to display on a panelview. so, the machine comes down and stops at the I:0/4 XIO, which is a NC prox sensor, and when that happens i want to move 10 (the screen number on the Panelview that i want to display) into the N7 register that will control what screen is displayed on the Panelview. Once that screen is displayed i need to move 0 into that same N7 register so that the screen control gets turned back over to the HMI so a button can be pressed to acknowledge the message on screen.

problem is, if i dont use the Latch and Unlatch setup i posted, once the acknowledge button is hit on the HMI, since the machine is stopped and still on the sensor, it just pops the message up again. i havent been able to figure out a way only have this action happen once when the sensor is made, unless what i have written is the way it should be done, but i have my doubts.

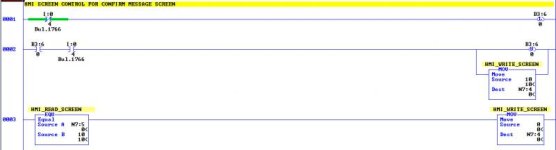

attached screenshot.

what im trying to do, using a ML1400 and a Panelview 800, is use a prox switch to trigger a screen to display on a panelview. so, the machine comes down and stops at the I:0/4 XIO, which is a NC prox sensor, and when that happens i want to move 10 (the screen number on the Panelview that i want to display) into the N7 register that will control what screen is displayed on the Panelview. Once that screen is displayed i need to move 0 into that same N7 register so that the screen control gets turned back over to the HMI so a button can be pressed to acknowledge the message on screen.

problem is, if i dont use the Latch and Unlatch setup i posted, once the acknowledge button is hit on the HMI, since the machine is stopped and still on the sensor, it just pops the message up again. i havent been able to figure out a way only have this action happen once when the sensor is made, unless what i have written is the way it should be done, but i have my doubts.

Last edited: