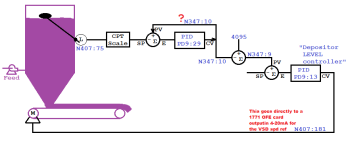

I have updated drbitboys picture.Also, I just noticed, from Post #4 of OP,

From the little we know, here is how this small part of the process appears to be designed to operate.

- that the CV output of PD9:29, also N347:10, which should have a range of 0-4095 from the PID, has an offset of 1627 substracted and the result put into N347:9

- there is no name or description on N347:9

- 1627 is 40% of the available output range of the PID, and

- that N347:9 value with the offset is used as the PV input into the next PID, PD9:13, and

- the CV output of that PD9:13 PID is scaled with a CPT to F8:50 named DEPOSITOR_SYRUP_LEV with a description of "DEPOSITOR SYRUP LEVEL," and

- The F8:50 value is MOVed to N522:10 named O_M010502_VHZ with a description of "Depositor Main Drive"

Those duplicate PV/CV parameters (N347:10) are a either a clever puzzle or an error. Is N347:10 written to anywhere else?

Where does the SP for PID PD9:13 come from?

N347:10 is only used in the PID and the SUB after the PID.