fishin_fl

Member

I recently started some machine addons to a wrapper line. We have the process working well for the addons. We were looking at already programmed states for the manual and auto tension logic within Rslogix 5000. We were told that this had not been looked at in years. After looking into it we have a very basic control, and I mean basic. Look at a setpoint and if not at setpoint step up or down by 0.0001. No wonder the auto tension is constantly all over the place. There is no feedback in logic saying how fast the line is accelerating or decelerating, FPM, Size of tape pad diameter, inertia.

Although, the machine does have inputs coming into plc compact logix.

1. Encoder feedback from Master Capstan drive

2. Encoders on each wrap head

3. Analog Lasers looking at pad dia for runout.

4. Line load cells, amplifers, and isolated power supplies for clutches for each tape pad.

I set out to understand the machine and the process since this programming is new to me. I have attached an image of the machine and some of the processes with the independent and states.

To explain the process, we wrap the tape around a wire. Wire gauges change, tape sizes change and speeds change per the profile.

Machine configuration from the posted image.

1. Wire comes into the machine from a payoff.

2. Setpoint FPM is set to Capstan from HMI.

3. The two wrapping heads are set to an RPM, based on Profile.

4. Machine acceleration and deceleration are set on HMI. Capstan and both heads follow ramp speed.

5. Tension is set on HMI in two forms.

a. Manual- Set by the voltage of 0-10 Vdc

b. Auto- Set by lbs. of 0-10 lbs.

6. The wrap head rotates independently from tape pad.

7. The wrap head pulls the tape off spindle center hysteresis.

8. The tension transducer downline from each wrap head send feedback to the plc.

Added: I installed Banner analog lasers to bring diameter reading into the machine to see pad size and display to HMI what material is on the tape pad.

What I am wanting to do:

I would like to use the Pad diameter to estimate roll inertia upon weighting the pad and adding center spindle wt. starting and stopping the machine to assist in better tension adjustment. This will help machine time and breaking the web with start/stop states also having master FPM encoder feedback.

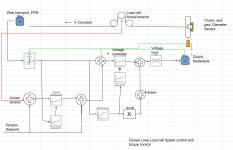

Secondly, when the machine is in steady-state control the tension in a PI scenario.

1. I have done some research and found that I would not want to do a full PID closed-loop design because upon startup and shutdown tension will be outside the dead bands which would cause unstableness and web breaks.

2. I would want to do an inner loop and an outer loop.

a. Inner loop looking at tension feedback

b. Outer loop looking at Line speed (FPM)

3. Laser Diameter sensors could be additional help with the start/stop control.

What I am asking:

I am needing help in the direction of constructing the logic. Some help laying the loop out.

Am I going in the right direction?

Are an inner loop and outer loop strategy going to benefit the system control?

Would this be considered a feed-forward system?

I know this is a long write up but wanted to provide a lot of information upfront. Thank you for the time to read.

Although, the machine does have inputs coming into plc compact logix.

1. Encoder feedback from Master Capstan drive

2. Encoders on each wrap head

3. Analog Lasers looking at pad dia for runout.

4. Line load cells, amplifers, and isolated power supplies for clutches for each tape pad.

I set out to understand the machine and the process since this programming is new to me. I have attached an image of the machine and some of the processes with the independent and states.

To explain the process, we wrap the tape around a wire. Wire gauges change, tape sizes change and speeds change per the profile.

Machine configuration from the posted image.

1. Wire comes into the machine from a payoff.

2. Setpoint FPM is set to Capstan from HMI.

3. The two wrapping heads are set to an RPM, based on Profile.

4. Machine acceleration and deceleration are set on HMI. Capstan and both heads follow ramp speed.

5. Tension is set on HMI in two forms.

a. Manual- Set by the voltage of 0-10 Vdc

b. Auto- Set by lbs. of 0-10 lbs.

6. The wrap head rotates independently from tape pad.

7. The wrap head pulls the tape off spindle center hysteresis.

8. The tension transducer downline from each wrap head send feedback to the plc.

Added: I installed Banner analog lasers to bring diameter reading into the machine to see pad size and display to HMI what material is on the tape pad.

What I am wanting to do:

I would like to use the Pad diameter to estimate roll inertia upon weighting the pad and adding center spindle wt. starting and stopping the machine to assist in better tension adjustment. This will help machine time and breaking the web with start/stop states also having master FPM encoder feedback.

Secondly, when the machine is in steady-state control the tension in a PI scenario.

1. I have done some research and found that I would not want to do a full PID closed-loop design because upon startup and shutdown tension will be outside the dead bands which would cause unstableness and web breaks.

2. I would want to do an inner loop and an outer loop.

a. Inner loop looking at tension feedback

b. Outer loop looking at Line speed (FPM)

3. Laser Diameter sensors could be additional help with the start/stop control.

What I am asking:

I am needing help in the direction of constructing the logic. Some help laying the loop out.

Am I going in the right direction?

Are an inner loop and outer loop strategy going to benefit the system control?

Would this be considered a feed-forward system?

I know this is a long write up but wanted to provide a lot of information upfront. Thank you for the time to read.