Hi there,

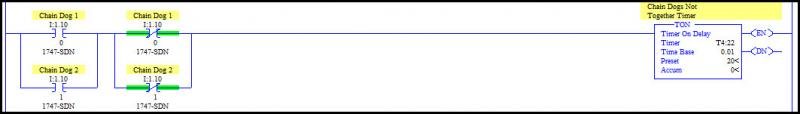

I am trying to create a Fault Logic, the scenario is 2 chains that should be running essentially at same speed. I have 2 proximity sensors reading a chain dog on each chain, the dogs have to be sensed at same time to be NO Fault, if they are not sensed at same time this should trigger a Fault and I will use this to stop my system. Obviously conditions that could happen are Chain Dog #1 sensed before Chain Dog #2 and vice-versa. I am using Contrologix PLC V20 with RSLogix 5000, Any ideas ? Thanks for your feedback

I am trying to create a Fault Logic, the scenario is 2 chains that should be running essentially at same speed. I have 2 proximity sensors reading a chain dog on each chain, the dogs have to be sensed at same time to be NO Fault, if they are not sensed at same time this should trigger a Fault and I will use this to stop my system. Obviously conditions that could happen are Chain Dog #1 sensed before Chain Dog #2 and vice-versa. I am using Contrologix PLC V20 with RSLogix 5000, Any ideas ? Thanks for your feedback