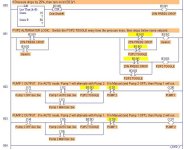

I need to create a system of 2 alternating pumps in ladder logic. I am using RSLogix 5000

2 pumps controlled in 3 modes (OFF, Manual and Auto).

OFF=Out of service

Manual=Stop (NC), Start (NO), Reset either pump.

Auto= Stop(NC), Start(NO), Reset - One pump starts and the other is on standby, the pump that is started first in auto will make the other its standby

I want to make it so that if the main pump is running and drops below 25% pressure the opposite pump will start automatically and the original pump will shut down and the reset light/switch will activate. Both pumps can never run at the same time

I searched the forums and saw a couple threads that seem like they might give me a good start but most of the programs are using micro 1000 like this thread.

http://www.plctalk.net/qanda/showthread.php?t=9499&page=3

Still a super novice at PLCs

2 pumps controlled in 3 modes (OFF, Manual and Auto).

OFF=Out of service

Manual=Stop (NC), Start (NO), Reset either pump.

Auto= Stop(NC), Start(NO), Reset - One pump starts and the other is on standby, the pump that is started first in auto will make the other its standby

I want to make it so that if the main pump is running and drops below 25% pressure the opposite pump will start automatically and the original pump will shut down and the reset light/switch will activate. Both pumps can never run at the same time

I searched the forums and saw a couple threads that seem like they might give me a good start but most of the programs are using micro 1000 like this thread.

http://www.plctalk.net/qanda/showthread.php?t=9499&page=3

Still a super novice at PLCs