You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

If someone can kindly check the problem

- Thread starter arnabbanik

- Start date

Mickey

Lifetime Supporting Member

Looks good.

The only thing I would do different is check the output being on first, then branch down to check the push button - that way the scan of the PLC won't have to check the PB(that's only on once every few million scans) then branch down & see that the output is already on to keep it on.

On a large program the additional scan steps can add up - best to start off in the right mindset.

I always check the most-common-on first & branch down to the least-common-on, and for checking the run conditions after the branch I start with the least-common-on & progress to the most-common-on so that when the least-common-on item drops the rest of the line is not scanned - it jumps right to the output to turn it off.

On a large program the additional scan steps can add up - best to start off in the right mindset.

I always check the most-common-on first & branch down to the least-common-on, and for checking the run conditions after the branch I start with the least-common-on & progress to the most-common-on so that when the least-common-on item drops the rest of the line is not scanned - it jumps right to the output to turn it off.

Last edited:

arnabbanik

Member

OP

Thanks Mickey and Aabeck.

So , should I put a check on the inputs PB's and the O/P? If the O/P(motor) is on, then jump and ignore the other steps? Is that what you meant? if you can explain little further and give me an example, it will be easier for me to understand.

Thanks!

So , should I put a check on the inputs PB's and the O/P? If the O/P(motor) is on, then jump and ignore the other steps? Is that what you meant? if you can explain little further and give me an example, it will be easier for me to understand.

Thanks!

Ronnie Sullivan

Member

They have used a N/O stop button instead of N/C

Even the question setter has not got the importance of N/C stop buttons.

Even the question setter has not got the importance of N/C stop buttons.

arnabbanik

Member

OP

They have used a N/O stop button instead of N/C

Even the question setter has not got the importance of N/C stop buttons.

Hi Ronnie,

Hence I used XIC check for the stop button. Can you please explain little but what can be done better and what is the harm of doing it the way I did.

Thanks!

Steve Bailey

Lifetime Supporting Member + Moderator

arnabbanik,

Your program is correct for the way the system is defined. Ronnie's objection is with the instructor's design of the system.

Because the instructor has specified a NO contact on the stop pushbutton, if one of the wires to the button should become disconnected, the pump could be started, but not stopped by the stop button. If the instructor had specified a NC contact, a disconnected wire to the stop button would prevent starting as well as stopping a running pump.

Your program is correct for the way the system is defined. Ronnie's objection is with the instructor's design of the system.

Because the instructor has specified a NO contact on the stop pushbutton, if one of the wires to the button should become disconnected, the pump could be started, but not stopped by the stop button. If the instructor had specified a NC contact, a disconnected wire to the stop button would prevent starting as well as stopping a running pump.

arnabbanik

Member

OP

arnabbanik,

Your program is correct for the way the system is defined. Ronnie's objection is with the instructor's design of the system.

Because the instructor has specified a NO contact on the stop pushbutton, if one of the wires to the button should become disconnected, the pump could be started, but not stopped by the stop button. If the instructor had specified a NC contact, a disconnected wire to the stop button would prevent starting as well as stopping a running pump.

Thanks Steve,

I was thinking on the same lines. How can I take care of this problem.If I assume it is NC button, then should I check for XIC? In that way, if wire is broken, it stops the motor?

Steve Bailey

Lifetime Supporting Member + Moderator

You can't assume a NC pushbutton. The instructor specifically stated that the X1 signal is true when the button is pressed. That's a NO contact. It is an inherent property of the system as designed that a likely mode of failure will result in an undesirable condition.

It is certainly possible for a NC pushbutton to fail such that the pump can no longer be stopped. For instance, if the NC contact block on the stop pushbutton became disengaged with the pushbutton mechanism, the pump could not be stopped by the button.

It is certainly possible for a NC pushbutton to fail such that the pump can no longer be stopped. For instance, if the NC contact block on the stop pushbutton became disengaged with the pushbutton mechanism, the pump could not be stopped by the button.

...should I put a check on the inputs PB's and the O/P? If the O/P(motor) is on, then jump and ignore the other steps? Is that what you meant? if you can explain little further and give me an example, it will be easier for me to understand...

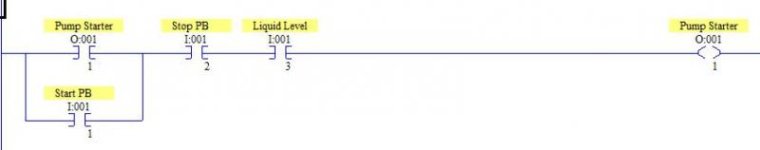

Here's a picture of the order I would put the checks in, thus improving scan time for the PLC. And as noted before I did make the StopPB a NC that always has to be on for the motor to run.

In this case that is wrong in the program, because the definition of the physical STOP button in the problem is backwards (Normally Open), compared to the way real STOP buttons should be configured (Normally Closed).And as noted before I did make the Stop PB a NC that always has to be on for the motor to run.

It is difficult to fix a basic error by introducing another error.

Last edited:

arnabbanik

Member

OP

Here's a picture of the order I would put the checks in, thus improving scan time for the PLC. And as noted before I did make the StopPB a NC that always has to be on for the motor to run.

Thanks a lot, much appreciated! I will incorporate it in my program, so that I don't forget.

Also, can you or anyone here tell me, even though I am performing division with integer function, the math register bit(S13 and S14) is not changing? I read about it from the rockwell manual and it says, remainder and quotient are stored there but I can not see anything but 0.Any ideas?

I was trying to do a even/odd check for a problem.

If you do, your instruction for the Stop PB (as given in the problem) will be incorrect.Thanks a lot, much appreciated! I will incorporate it in my program, so that I don't forget.

gbradley

Lifetime Supporting Member

Here's a picture of the order I would put the checks in, thus improving scan time for the PLC. And as noted before I did make the StopPB a NC that always has to be on for the motor to run.

In my attached drawing, Will Rung 0 scan faster than Rung 1?

I realize you wouldn't actually put two rungs like this together in a program.

Similar Topics

It finally happened. I work for an OEM and a customer has spec'ed all Siemens PLC hardware. Normally we use either Mitsubishi or GE but they chose...

- Replies

- 11

- Views

- 2,581

Does anyone know of a way to detect if someone is online with the controller in ControlLogix (from logic)

I'm thinking that maybe there is a CIP...

- Replies

- 7

- Views

- 387

Long story short lost our parameter setup for an indradrive m. I have these files saved as backups but dont know how to open them. Can someone...

- Replies

- 12

- Views

- 900

If a programmable controller controls the operation of

a motor, what connects motor control to the PC?

A) Line voltage

B) I/O device

C) Modem

D)...

- Replies

- 27

- Views

- 7,101

I can't find what laptop I have our PanelBuilder32 application and license on. And Rockwell no longer supports it. Can someone please update 1...

- Replies

- 5

- Views

- 1,627