medensat

Member

Hello ,

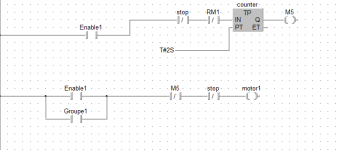

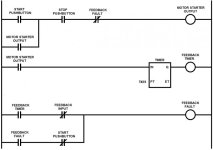

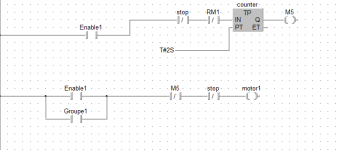

I want feedback from the relay that controls the motor, in this relay there is a contact(RM1) that I'll use as input to the PLC that will inform me that the relay is on if I order. if the contact is opened the relay does not work, if it is closed the relay is on.

this is what I do:

if I press button Enable1 2second must wait for the motor to be running in the problem is that if the contact(RM1) is open the motor remains running

I want feedback from the relay that controls the motor, in this relay there is a contact(RM1) that I'll use as input to the PLC that will inform me that the relay is on if I order. if the contact is opened the relay does not work, if it is closed the relay is on.

this is what I do:

if I press button Enable1 2second must wait for the motor to be running in the problem is that if the contact(RM1) is open the motor remains running