skymadgaz

Member

Hi All.

I apologise if this topic is already covered in another thread.

I currently have an encoder connected to an HSCE high speed counter card that is measuring the running speed of the machine.

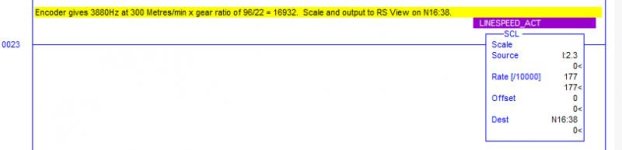

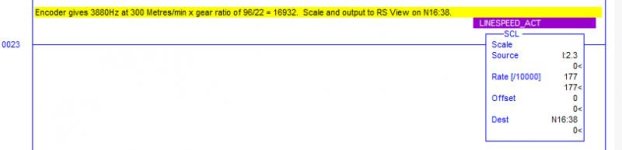

The comment in the program where this is scaled in to linespeed (meters / minute) states :-

Encoder gives 3880Hz at 300 Metres/min x gear ratio of 96/22 = 16932. Scale and output to RS View on N16:38

A new requirement on this line is now to utilise the output from the HSCE card to give 1 pulse for ever meter of material that passes through the line.

I would appreciate any help on how I could go about this (if it is possible)

Many Thanks

I apologise if this topic is already covered in another thread.

I currently have an encoder connected to an HSCE high speed counter card that is measuring the running speed of the machine.

The comment in the program where this is scaled in to linespeed (meters / minute) states :-

Encoder gives 3880Hz at 300 Metres/min x gear ratio of 96/22 = 16932. Scale and output to RS View on N16:38

A new requirement on this line is now to utilise the output from the HSCE card to give 1 pulse for ever meter of material that passes through the line.

I would appreciate any help on how I could go about this (if it is possible)

Many Thanks