drbitboy

Lifetime Supporting Member

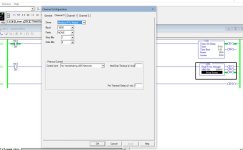

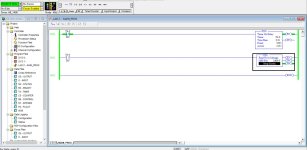

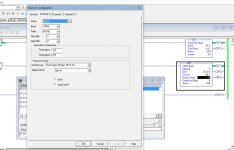

I just remembered something: the MicroLogix 1400 implements the Modbus TCP protocol over Integral Channel 1. So if pyModSlave or something similar can be set up to also communicate via Modbus TCP, then you could at least prove that you have the Modbus Master on the 1400 set up correctly, which we are pretty sure is already true. Success would point to the physical receiver side of Integral Channel 0's transceiver as the problem, and failure would point to a (subtle?) issue in your Modbus configuration.

Were you able to get anywhere with the 37h error code and that TechConnect article that @MikeyN mentioned?

Were you able to get anywhere with the 37h error code and that TechConnect article that @MikeyN mentioned?