Here's the logic... I added a truncate instruction to clean it up... Like I said, the value just increases and holds; it never falls... (It also takes a long time to stabilize; not much better than the my other time/average setup that I started with...)

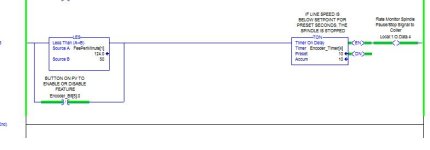

I've also included another rung of logic (second picture); this is where I'm trying to use the line speed value as a control feature to error-proof my encoder (in case the wheel loses traction with the product...). I'll probably develop some alarm features with that too, but for now I just need a fast, real-time value for this logic...

I read a couple of posts that said I could change my encoder to velocity, but I'm not sure what that would do to my current counter logic... I'm open to learning more though...

Thanks,

John