How are you going to select the order ?

Do you have an HMI or are you using buttons into I/O ?

If using buttons then there may be a problem how do you select the order, for example if you use the start buttons what is to stop you pressing a button twice i.e. order becomes 1,1,2,3 etc.

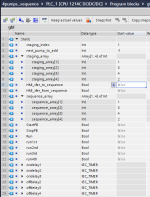

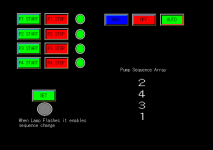

If using an HMI you can have lots of buttons & possibly an array for the sequence so you populate the array with the pump order.

Example:

All pumps must be stopped, this allows you to change the order in the array, have some logic that if you end up with the same pump in two or more of the array locations it errors or zero's the array.

Using just a few discreet buttons the logic would become rather complex & without some indication of what order how do you know ?.

Do you have an HMI or are you using buttons into I/O ?

If using buttons then there may be a problem how do you select the order, for example if you use the start buttons what is to stop you pressing a button twice i.e. order becomes 1,1,2,3 etc.

If using an HMI you can have lots of buttons & possibly an array for the sequence so you populate the array with the pump order.

Example:

All pumps must be stopped, this allows you to change the order in the array, have some logic that if you end up with the same pump in two or more of the array locations it errors or zero's the array.

Using just a few discreet buttons the logic would become rather complex & without some indication of what order how do you know ?.