drbitboy

Lifetime Supporting Member

No sure what the highlighted section means (maybe "double" was supposed to be "doable?").Wanting to set between 20 - 50Hz, its in NZ hence not ~60. But to give some deadband was thinking to start at ~22.5Hz

Its a small plant, doing between 10 - 20 m3/h. If I turned on the pump at 20Hz and with the valve fully open, it'll do ~22m3/h. So thereabouts on the top end of my range, but double on the bottom.

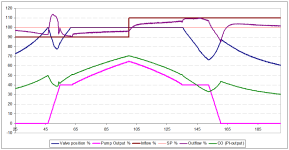

I'm expecting the control valve would need to be around 45% open with the pump at minimum speed to bring it to 10m3/h (~75% BEP).

Anyway, if the pump running at minimum (20Hz) can exceed the maximum expected inflow (> 20m3/h), then there is no reason to control flowrate with the VFD speed reference, as the least wasteful flow control method when pumping would be to continue to use the valve. I.e. the way to minimize energy usage would be to run the pump at the minimum speed (20-22.5Hz), as

- any higher pump speed would require throttling the valve down further, which would use more energy.

- and any lower pump speed would be below the minimum.

Last edited: