I received the .dnt files from the customer.

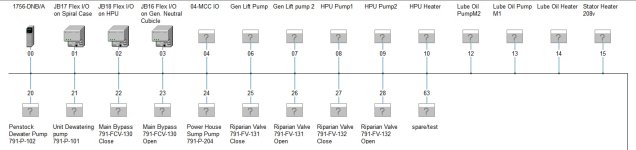

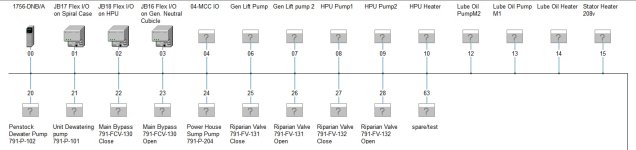

The one I'm most interested in is the one pictured in the screen shot at the bottom. Some of you should even be able to understand the nature of what I'm dealing with from the descriptions but that's not the point, no sensitive information there.

Basically, they're polling all of that from one PLC, I need now to segregate Node 20 to 28 (those are the nodes, right?) to another PLC / 1756-DNB. It kind of look straightforward enough but I still have a lot of questions.

From the "new" DWG they provided, I can now tell that I was right and most of these starters are in fact WPONIDNA DeviceNet modules, but still won't have the CWD to figure the order they're connected.

-For background, we're reprogramming 2 X L7X into 3 X L8X (not sure why yet) and some of the MCC stuff belongs now in the new 3rd PLC;

-Let start with let say Node 20, Penstock Dewatering Pump. From the RSNetworx config it's Node 20). In PLC, I'm looking at location like Local:5:I.Data[30].X for 4 DI, So there is probably somewhere in RsNetWorx I can find that remap. I don't know where it is declared. I'm kind of getting the idea for the IO Flexs, but are the WPONIDNA addresses static so it's always the same structure? (Fault, Running, Ready, Auto);

-Is there a way to associate the .dnt with the actual PLC program? Or is it 2 completely separated instances that doesn't belong together?

-Nodes are looking like they are already assigned. Would it have any incidence if I switched the position (I mean wiring here) between 2 of them. This is a parallel daisy chain with addresses on each device, so my guess would be that the actual devices order / position in the chain doesn't matter at all. Am I right?

-Someone mentioned that serial number are used when attributing a Node or something like that. Question A)Do we configure node # using RSNetWorx or is is another software? B) Is the Node "aligned" with a serial number or it's just a device with a node # on the network? My understanding is that when the cut-over is done, I just need to re-use the same Nodes as they are "registered" into the devices, but since it's a new .dnt config, I'm not confident with it. I won't have access to any of that before the cut-over outage, so I want to be prepared;

-I have a lot of warnings right now and also when I try to "open" a Device:

"The device at address 04 has been redefined to use a different applet. Since the device's configuration could not be maintained, it has been reset to the default values."

and

"The device at address 28 is not registered on this computer."

Will it be an issue at some point?

-I know there are "EDS" files that are associated with that kind of setup. I found some related to those Cutler-Hammer DeviceNet Starters devices. I haven't worked with Rockwell / AB in a while so I'm not sure what is the purpose of those, but my guess is that is pretty important to make it work.

-Any insight on what to look for, how to proceed or what I missed that would be a show stopper when on site?

I'm asking a lot I know. If you have questions regarding Unity Pro, Citect or Vijeo Designer, I may can help you until I become more fluent with Rockwell.

Thanks.