A computer model

how is the air* coming into the space on which the vacuum is being pulled? Is it a process (e.g. heat exchanger, or burner flue), leakage, or a valve? If it's a process or a valve, does it ever change (i.e. control valve, run burner at a different rate)?

* I assume it's air

The actual system reaches an equilibrium when the flow rate of air coming into the system (call that flow leakage, or fIn) equals the rate of air being pulled out by the fans (fOut).

Assuming turbulent flow, the pressure differential (ΔP) is roughly proportional to the square of fIn, IIRC, ΔP = Cf**-2 fIn**2 (cf. [system resistance] curves below). Cf is the system flow coefficient (Cv) divided by the the square root specific gravity (sqrt(SG))for fIn. SG will change with pressure but we will ignore that for this model.

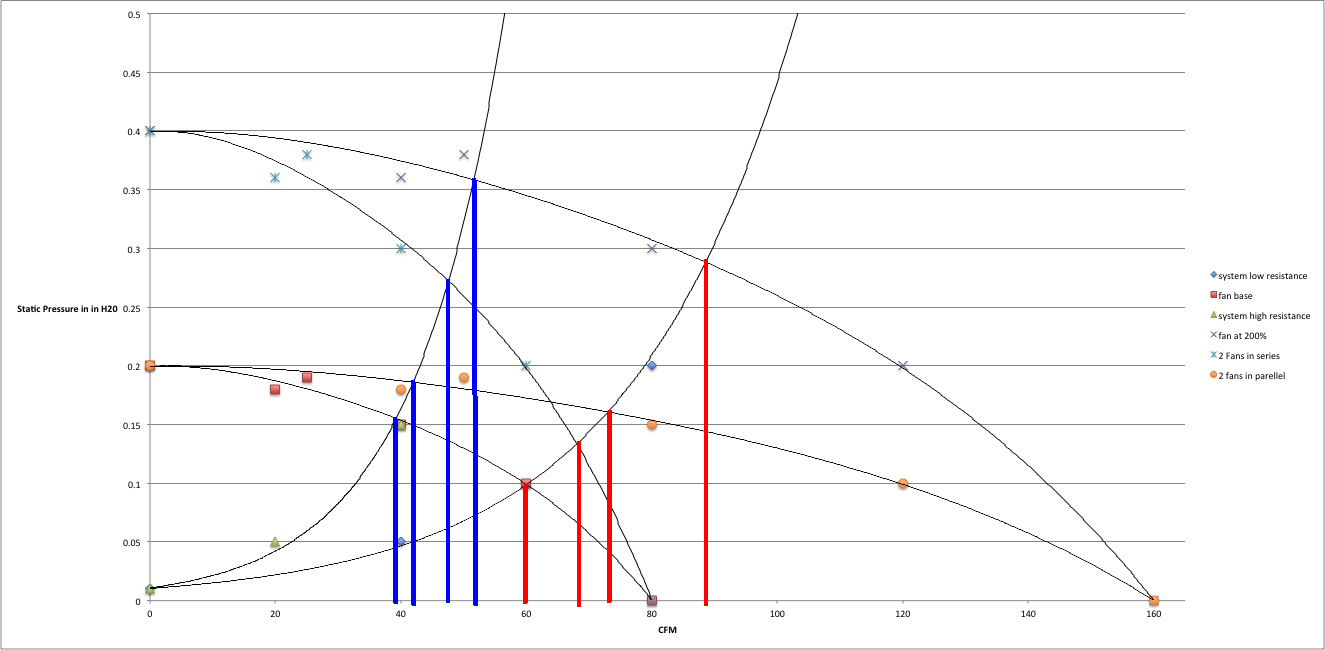

At the fans, the driven flow, fOut, decreases with increasing ΔP according to a fan curve e.g.

The fan speed (Hz, which may be one of the control inputs) moves that curve in and out wrt the origin (cf. [fan base] vs. [fan at 200%] curves above). The number of fans scales the flow along the abscissa without changing its extent along the ordinate (cf. [fan base] vs. [2 fans in parallel] curves above). Ignore the fans in series curve.

Those fan curves look like an inverse square root curve; that is

not even close to exact but probably good enough for a simulation**. So ΔP = sqrt((fMax - fOut) / K); K is a fan curve coefficient roughly proportional to the fan speed; fMax is directly proportional both to the number of fans and to the fan speed (to first order).

At equilibrium, the ΔP and flow for both models will be the same, i.e.

- Cf**-2 fIn**2 = ΔP = sqrt((fMax' - fOut) / K)

- fIn = fOut = f'

- K Cf**-4 f'**4 = (fMax' - f')

- fMax' = f' + K Cf**-4 f'**4

That is the basic form of the equation we need to solve for f', and then drop f' back into the ΔP equation. We'll get to the prime in f' and fMax' in a bit.

More

first-order modeling:

- FC = number of fans running

- FS = fan speed, Hz

- fMax' = A FC * FS

- max flow at zero ΔP is proportion to FC and FS

- K = B / FS**2

- max ΔP at zero flow is proportional to FS

So we need to solve for A and B, also f' at ΔP=3", but we only have two datapoints (3" ΔP with 4 fans at 50Hz, and with 3 fans at 60Hz). However, we don't need the actual values of fMax' and f', so if we make the following substitutions

- fMax = fMax' / A

- f = f' / A

then we can say

which basically re-scales the abscissa of the plot, replaces fMax' and f' with fMax and f, respectively, and rolls some power of the constant A into A and Cf, such that A becomes 1, and Cf is TBD, leaving us with only B and f to solve for from two data points in this equation:

- ΔP = sqrt((fMax - f) / K)

substituting ...

- ΔP = sqrt((FC FS - f) / (B / FS**2))

- ΔP = sqrt((FC FS**3 - f FS**2) / B)

- B ΔP**2 = FC FS**3 - f FS**2

Using the two known cases:

- B 3**2 = B 9 = 3 60**3 - f 60**2 = 648000 - 3600 f

- B 3**2 = B 9 = 4 50**3 - f 50**2 = 500000 - 2500 f

Subtracting previous equation from second-previous, solve for f and B:

- 0 = 148000 - 1100 f

- f = 134.545

- B = (648000 - 3600 134.545) / 9 = 18181.8

- B = (500000 - 2500 134.545) / 9 = 18181.8 (double check)

Solve for Cf**-4

- Cf**-2 f**2 = ΔP

- Cf**-2 = ΔP f**-2 = 3 134.545**-2 = 1.66e-4

- Cf**-4 = 2.746e-8

Now we move back to the model equation i.e.

- fMax = f + Cf**-4 K f**4

- fMax = f + Cf**-4 B FS**-2 f**4

- fMax = f + 4.99e-4 FS**-2 f**4

- FC FS = f + 4.99e-4 FS**-2 f**4

From the general form of that equations, fMax = f + m f**4, with fMax, f, and m all non-negative, f will always be between 0 and fMax, and dfMax/df is always positive

So one approach to a solution would be a binary search between 0 and fMax:

- Set fMax = FC FS

- set fHi = fMax

- Set fLo = 0

- Loop:

- Set fEst = (fHi - fLo) / 2

- calculate fMaxEst = fEst + 4.99e-4 FS fEst**4

- if fMaxEst > fMax, set fHi = fEst

- else set fLo = fEst

- Exit loop when (fHi-fLo) is small (TBD)

- 10 passes gets fEst to within (0.1% fMax) of f

Another approach would be Newton-Raphson, starting from fEst = fMax (= FC FS):

- fMaxEst = fEst + 4.99e-4 FS fEst**4

- dfMaxEst/df = 1 + 15.97 FS fEst**3

- ΔfMaxEst = (fMax - fMaxest) / (dfMaxEst/df)

- fEst = fExt + ΔfMaxEst

- Loop until ΔfMaxEst is small

Either way, once you have fEst, calculate the differential pressure

** Every computer program is a model of something in the real world; the only real choice is the level of fidelity; everything else flows from that.