hi All

I am completely green in Mitsubishi PLC (i used to program siemens) but need kepware to connect to FX3U pls with ENET adp module.

Could somebody pls help me with the very basics as kepware does not talk to the FX3U yet:

Regards

I am completely green in Mitsubishi PLC (i used to program siemens) but need kepware to connect to FX3U pls with ENET adp module.

Could somebody pls help me with the very basics as kepware does not talk to the FX3U yet:

- What software do i need to read configuration/potentially do changes to FX3U and ENET? - is it free?

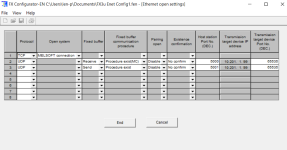

- How to check the port that the PLC is using - i assumed 5001 as default but it did not work- it is FX3 setting or ENET module setting?

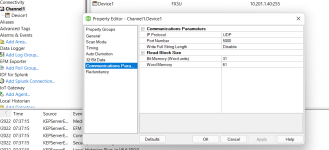

- What kepware driver is best for the FX3 with ENET module? - at the moment ethernet driver seemed obvious choice to me

- Does ENET adp adapter can server only 1 connection at the time - is it hardware limit or something i can configure in the PLC?

- I will be trying to read strings from FX but how are these strings normally stored in mitsubishi FX3? - i found in the documentation that its either DSL or DSH area - is it something that has to be configured upfront or can i just use either DSL or DSH memory area?

Regards