Palm Beacher

Member

Hi All,

It probably has been discussed before....but...

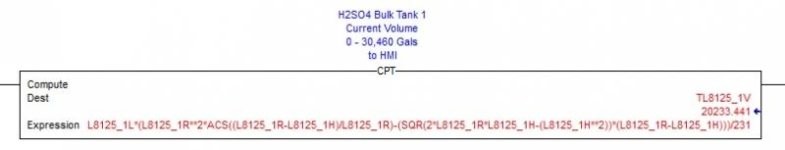

My PLC is a AB L71 Processor (RSLogix5000 v20)

I have a Horizontal Round Cylinder Tank with Flat Ends.

I know the Length (864") and Diameter (94") and Radius (47") of the tank, and I have a

level transmitter to give me the height of the liquid inside in inches.

What formula do I use in my PLC to calculate the Volume inside

the tank.??

Thanks for your help,

Palm Beacher

It probably has been discussed before....but...

My PLC is a AB L71 Processor (RSLogix5000 v20)

I have a Horizontal Round Cylinder Tank with Flat Ends.

I know the Length (864") and Diameter (94") and Radius (47") of the tank, and I have a

level transmitter to give me the height of the liquid inside in inches.

What formula do I use in my PLC to calculate the Volume inside

the tank.??

Thanks for your help,

Palm Beacher

Last edited: