unsaint32

Member

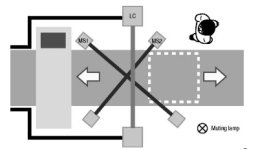

We have a muting light curtain setup like the picture I am attaching here. However, a pallet sometimes hits the photo eyes (MS1 & MS2 in the picture) and they get out of alignment. If one misaligns, next pallet going through the light curtain shuts the system power. Then I know the muting did not work and I can fix it. Here is the problem... if both of them misalign, it's same as the muting condition, so next pallet going through the light curtain does not shut down the machines. At the same time, anybody can walk through the light curtain and nothing shuts down. The muting relay is Sick UE410-MU. I am requesting to install two pilot lights to indicate the photo eyes misalignment. But is there a better solution?