I think the problem here is that the sensors are NC, so when they are misaligned they give a signal to the muting system. If the muting system can have the input logic reversed, change the sensors to NO operation so that when they are misaligned they don't fool the muting system.

JRoss,

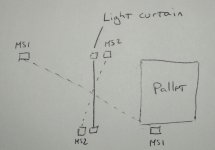

our UE410-MU needs two 24V inputs for its muting to begin. Muting is designed to be in effect when a part breaks the cross beams, right? So, I need the sensors to send 24V to the UE410 when a part breaks the beams. With the sensors on NO operation, breaking the beams will send 0V inputs to the UE410.