AmazingNoob

Member

Hi there,

I am trying to determine the input, output, and config assembly and entering it into a beckhoff plc, and couldn''t get proper active connection.

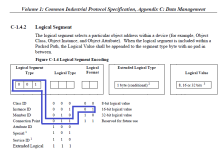

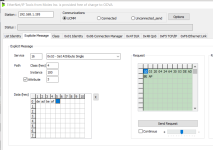

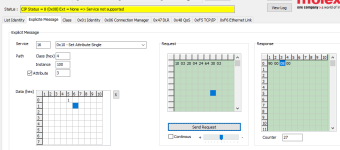

As i was looking at the Path:

"20 04 24 66 2D 00 [Param4] 2D 00 [Param3]"; $ Path

Config assembly: 102 (Dec) (66 Hex)

Input assembly : 101 (Refer to Param3: Would value be 101 Dec???)

Output assembly: 100 (Refer to Param4: Would value be 100 Dec???)

I am trying to determine the input, output, and config assembly and entering it into a beckhoff plc, and couldn''t get proper active connection.

As i was looking at the Path:

"20 04 24 66 2D 00 [Param4] 2D 00 [Param3]"; $ Path

Config assembly: 102 (Dec) (66 Hex)

Input assembly : 101 (Refer to Param3: Would value be 101 Dec???)

Output assembly: 100 (Refer to Param4: Would value be 100 Dec???)

Code:

[Params]

Param1 =

0, $ reserved, shall equal 0

,, $ Link Path Size, Link Path

0x0000, $ Descriptor

0xC7, $ Data Type

2, $ Data Size in bytes

"Input Size", $ name

"", $ units

"", $ help string

0,64,64, $ min, max, default data values

,,,, $ mult, div, base, offset scaling

,,,, $ mult, div, base, offset links

; $ decimal places

Param2 =

0, $ reserved, shall equal 0

,, $ Link Path Size, Link Path

0x0000, $ Descriptor

0xC7, $ Data Type

2, $ Data Size in bytes

"Output Size", $ name

"", $ units

"", $ help string

0,64,64, $ min, max, default data values

,,,, $ mult, div, base, offset scaling

,,,, $ mult, div, base, offset links

; $ decimal places

Param3 =

0, $ reserved, shall equal 0

,, $ Link Path Size, Link Path

0x0000, $ Descriptor

0xC7, $ Data Type

2, $ Data Size in bytes

"Input Assembly ID", $ name

"", $ units

"", $ help string

100,768,101, $ min, max, default data values

,,,, $ mult, div, base, offset scaling

,,,, $ mult, div, base, offset links

0; $ decimal places

Param4 =

0, $ reserved, shall equal 0

,, $ Link Path Size, Link Path

0x0000, $ Descriptor

0xC7, $ Data Type

2, $ Data Size in bytes

"Output Assembly ID", $ name

"", $ units

"", $ help string

100,769,100, $ min, max, default data values

,,,, $ mult, div, base, offset scaling

,,,, $ mult, div, base, offset links

0; $ decimal places

[Connection Manager]

Connection1 =

0x04010002, $ 0-15 = supported transport classes

$ 16 = trigger: cyclic

$ 17 = trigger: change of state

$ 18 = trigger: application

$ 19-23 = trigger: reserved

$ 24 = transport type: listen-only

$ 25 = transport type: input-only

$ 26 = transport type: exclusive-owner

$ 27 = transport type: redundant-owner

$ 28-30 = reserved

$ 31 = Client = 0 / Server = 1

0x44640405, $ 0 = O->T fixed size supported

$ 1 = O->T variable size supported

$ 2 = T->O fixed size supported

$ 3 = T->O variable size supported

$ 4-5 = O->T number of bytes per slot (obsolete)

$ 6-7 = T->O number of bytes per slot (obsolete)

$ 8-10 = O->T Real time transfer format

$ 11 = reserved

$ 12-14 = T->O Real time transfer format

$ 15 = reserved

$ 16 = O->T connection type: NULL

$ 17 = O->T connection type: MULTICAST

$ 18 = O->T connection type: POINT2POINT

$ 19 = O->T connection type: reserved

$ 20 = T->O connection type: NULL

$ 21 = T->O connection type: MULTICAST

$ 22 = T->O connection type: POINT2POINT

$ 23 = T->O connection type: reserved

$ 24 = O->T priority: LOW

$ 25 = O->T priority: HIGH

$ 26 = O->T priority: SCHEDULED

$ 27 = O->T priority: reserved

$ 28 = T->O priority: LOW

$ 29 = T->O priority: HIGH

$ 30 = T->O priority: SCHEDULED

$ 31 = T->O priority: reserved

,Param2,, $ O->T RPI, size, format

,Param1,, $ T->O RPI, size, format

,, $ config #1 size, format

,, $ config #2 size, format

"I/O Connection", $ Connection Name

"", $ help string

"20 04 24 66 2D 00 [Param4] 2D 00 [Param3]"; $ Path