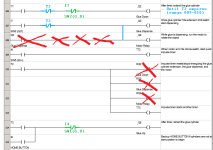

I am using a Schneider Electric PLC with Zelio Soft 2 programming software. I have gotten my program completely written up, and I have checked and tested it within the Simulation mode, and I believe it does exactly what I want it to do.

However, I am wondering if there is a way to build in a "reset to beginning" or "start from beginning" function. After the program has run through its whole sequence, all physical components (cylinders, motors, etc.) are back at their starting position...which is ideal! But, I want it to start back at the beginning with no outputs energized.

The machine uses an "On/Off" switch that must be flipped to on in order to start the program, and a button has to be held down for the duration of the process. I am hoping there is a way to release the hold button, and flip the switch off, then back on, thus "restarting" the process and code.

Is this possible? I can't seem to figure out a good way to do it.

However, I am wondering if there is a way to build in a "reset to beginning" or "start from beginning" function. After the program has run through its whole sequence, all physical components (cylinders, motors, etc.) are back at their starting position...which is ideal! But, I want it to start back at the beginning with no outputs energized.

The machine uses an "On/Off" switch that must be flipped to on in order to start the program, and a button has to be held down for the duration of the process. I am hoping there is a way to release the hold button, and flip the switch off, then back on, thus "restarting" the process and code.

Is this possible? I can't seem to figure out a good way to do it.