Please don't make me argue with ChatGPT, especially when it talks out of its language-model butt.

ControlLogix is "little-endian" and LSB-first. It always has been, and cannot be configured differently. The 1756, 1769, and 5069 controllers are all the same in that fundamental way.

What is important here is understanding how SLC/MicroLogix, ControlLogix, and Micro 800 store and address String data. That's slightly different between platforms and important to Stateline's application.

Without getting too deep into the weeds, a MicroLogix uses a 16-bit Word for the Length, and packs the characters two at a time into 16-bit words. The fixed memory allocation for an ST data table element in a PLC-5/SLC-500 or MicroLogix is that Length word plus 82 characters (so 42 total Words).

ControlLogix uses a 32-bit Double Word for the Length, and packs the characters one at a time into an SINT[x] array. The default length is 82 characters but additional String datatypes can be created with different lengths.

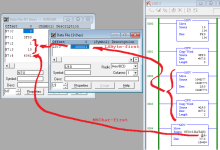

If the data is going to be written to a 5069 CompactLogix from a MicroLogix 1100, then it needs to be packed into an Integer data file first.

If it were me, I would prepend a transaction ID number, then the "Number" value as a Word (or two, if it's a Floating Point value), then the String Length, then 41 words of the String data. That's simple for the MicroLogix to originate a message to the CompactLogix on-demand and send all the data in one transaction.