Hi,

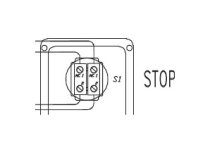

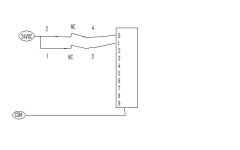

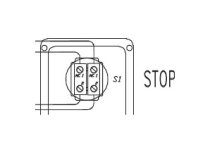

Im wondering how i have to make the circut for a emergency stop that have to normally closed relays and a push button. When i push the button i want both of the relays to be true and a lamp that show me that the emergancy stop is working. How will i write this in ladder logic and what are the inputs, how will i wire it in the real world.

Hope any one can answer and thank you

Im wondering how i have to make the circut for a emergency stop that have to normally closed relays and a push button. When i push the button i want both of the relays to be true and a lamp that show me that the emergancy stop is working. How will i write this in ladder logic and what are the inputs, how will i wire it in the real world.

Hope any one can answer and thank you