I am an aspiring control systems engineer. I have a lab right now that we use plcs and programs to control what motors do. I am racking my brain trying to figure out how to do this project that I have due.

I have everything to work save for having the selector switches killing the motors when either of the selector switches are flipped. The selector switches are dual position and they can only have a normally open contact block on the back of them. I can't add a normally closed contact block and then just add another input into the program.

My professor gave me a few hints but a couple of us tried to do what he suggested and failed miserably.

We are using rslogix 500.

Does anyone have any suggestions?

http://imgur.com/52IMVeR,4DzckLj

I can post the .rss file if it is needed.

I am not trying to cheat on this or anything but 2 out of the 20 people in my class figured this out and they aren't willing to help out.

Any help would be appreciated.

file: https://livedelhi-my.sharepoint.com...TB5E=&docid=0dbc5dc3f66964b4299d287201a8a63c8

Code:

[B]PLC Timer Project 6A (on delay) and 6B (off delay)[/B]

[B]6A Project[/B]

Whichever motor is selected by the switch will start first.

The other motor will start after 10 seconds

If either overload is tripped both motors will stop immediately and neither can be restarted until the overload is reset.

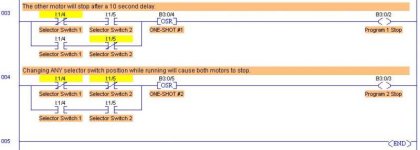

Changing the selector switch position while running will cause both motors to stop.

[B]6B Project[/B]

Both motors start when a Start button is pressed.

When stop is pressed the motor selected by the switch will stop immediately.

The other motor will stop after a 10 second delay.

Changing the selector switch position while running will cause both motors to stop.

If either overload is tripped both motors will stop immediately and neither can be restarted until the overload is reset.

[B]PLC Inputs[/B]

Stop

Stop

Start

Start

SS 1 Position 1 (Motor 1)

SS 1 Position 2 (Motor 2)

SS 2 Position 1 (Program 1)

SS 2 Position 2 (Program 2)

NO Overload Contact M1

NO Overload Contact M2

[B]PLC Outputs[/B]

Motor 1

Motor 2My professor gave me a few hints but a couple of us tried to do what he suggested and failed miserably.

Code:

[LIST]

[*]Have ONE rung control ONE motor. Having several rungs try to write to one output is a recipe for disaster.

[*]Use BINARIES. Five of them will help you immensely

[*]Remember that you can use the DN bits of timers in more than one place

[*]The entire project can be completed with one on-delay timer and one off-delay timer

[/LIST]Does anyone have any suggestions?

http://imgur.com/52IMVeR,4DzckLj

I can post the .rss file if it is needed.

I am not trying to cheat on this or anything but 2 out of the 20 people in my class figured this out and they aren't willing to help out.

Any help would be appreciated.

file: https://livedelhi-my.sharepoint.com...TB5E=&docid=0dbc5dc3f66964b4299d287201a8a63c8

Last edited: