You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PID tuning for Oven Temperature

- Thread starter michaeli

- Start date

Peter - to convert sopdt values above to K terms below for plc 5 using independent equation with pd block and derivative of PV would be as follows -

Kp = Kc = 0.130

Ki = Kc/Ti = 0.130/0.218 = .596/secs

Kd = Kc x Td = 0.130 x 0.023 = .0029 secs

Kp = Kc = 0.130

Ki = Kc/Ti = 0.130/0.218 = .596/secs

Kd = Kc x Td = 0.130 x 0.023 = .0029 secs

Peter Nachtwey

Member

Yes, but the gain I posted has units of %control_output/degree_error. This is not the gain you want use in the PLC because Rockwell PID gains are unitless. You need to do a conversion. Also my time constants are minutes since ISA PID time constants are in minutes.Peter - to convert sopdt values above to K terms below for plc 5 using independent equation with pd block and derivative of PV would be as follows -

Kp = Kc = 0.130

Ki = Kc/Ti = 0.130/0.218 = .596/secs

Kd = Kc x Td = 0.130 x 0.023 = .0029 secs

You need to get data with the oven running under consistent load. I don't think the initial data I got was good because the load varies too much.

The program I used is here

http://deltamotion.com/peter/Scilab/AutoTune/

It is a scilab program. I wrote the auto tune part. Some one else wrote a GUI.

You need to run the GainCalculaterGUI() function. See the other .csv or .txt files to get the right format.

Last edited:

It appears that there’s more going on here than a furnace temperature change in response to a step in power output (as depicted in plot in post #11). I wouldn’t try to fit this (raw) data with anything other than an eyeball. Those spurious spikes will cause problems for an otherwise properly tuned controller. Better would be to understand the sources that are producing those high frequency spikes and do something (if possible) to eliminate them from the process.

This looks like more than a tuning problem. PI(D) tuning can only get you so far in your quest for improved and more consistent process operation. There may be underlying processing issues with the furnace such as poor temperature sensor location, electrical noise, irregular airflow, drafts entering the furnace, or something else. Address these issues first and then revisit controller tuning.

This looks like more than a tuning problem. PI(D) tuning can only get you so far in your quest for improved and more consistent process operation. There may be underlying processing issues with the furnace such as poor temperature sensor location, electrical noise, irregular airflow, drafts entering the furnace, or something else. Address these issues first and then revisit controller tuning.

Peter Nachtwey

Member

Jamesau, I agree. There may be a need for keep track of objects on the conveyor.

Michael, does the temperature go up or down when the objects on the conveyor go by?

Michael, does the temperature go up or down when the objects on the conveyor go by?

pid tuning for oven temperatrue

Guys - oven/furnace is loaded manually by operator. most of product is similar but sometimes a heavier or lighter product part is loaded as needed by customer. spacing between product is kept similar but sometimes operator is out of product so then there can be a one unit gap on conveyor. for the bump test period of about 1 hour all attempts were made to keep all product the same but red arrows on temp graph show where a couple larger units were loaded. thinking good PID values could better keep these disturbances to temperature under control.

Guys - oven/furnace is loaded manually by operator. most of product is similar but sometimes a heavier or lighter product part is loaded as needed by customer. spacing between product is kept similar but sometimes operator is out of product so then there can be a one unit gap on conveyor. for the bump test period of about 1 hour all attempts were made to keep all product the same but red arrows on temp graph show where a couple larger units were loaded. thinking good PID values could better keep these disturbances to temperature under control.

OK.

So, what exactly, is going through the oven?

What is happening to what's going through the oven? Is it being dried? Is it being cured? Else?

What measure of product quality is affected most by variations in oven operation?

At 1200mm/min, how long does each part reside in the oven?

How else is the oven instrumented? (What other data is available)?

What constraints, if any, are there during the normal course of operation (that could damage the oven or render the product useless)?

Do you have any test data from an unloaded oven (no product throughput)?

So, what exactly, is going through the oven?

What is happening to what's going through the oven? Is it being dried? Is it being cured? Else?

What measure of product quality is affected most by variations in oven operation?

At 1200mm/min, how long does each part reside in the oven?

How else is the oven instrumented? (What other data is available)?

What constraints, if any, are there during the normal course of operation (that could damage the oven or render the product useless)?

Do you have any test data from an unloaded oven (no product throughput)?

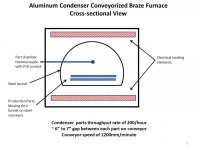

no fans in system. many call oven but really is a furnace. for brazing of aluminum heat exchangers. time in furnace is about 15 minutes. parts reach about 600c and at that temperature the aluminum parts fuse together so then heat exchanger is leak free. if final part temperature is to hot (>610c) or to cold (<585c) the heat exchanger can leak and then is scrap. furnace has several zones with first having set temperature of about 470 and last zone having temperature of about 600c. furnace has continuous steel tunnel about 18 meters in length. each zone is about 2 meters and has electrical elements above and below the tunnel. working first to tune pids for zone 1 with set temperature of 470c.

Individual PIDs will be ineffective. Disturbances will just propagate through the oven (by the time a controller responds to the upset, the part has long left the zone).

The hardest part of solving real-world problems, especially when collaborating with others, is to pose the problem properly, thoroughly, and in full context in the first place.

The hardest part of solving real-world problems, especially when collaborating with others, is to pose the problem properly, thoroughly, and in full context in the first place.

Last edited:

NetNathan

Lifetime Supporting Member

i buy a $600 dollar Azbil Temp controller (SDC35 is 1/8 din and SDC36 is 1/4 din) and slave it to the PLC analog IO.

It has 8 PIDs (called by temp ranges or Dig In) and a perfect AutoTune function. You can also buy software for it to configure, save configurations, and monitor/trend operation.

I have a bad taste for running PID in ladder logic. It always has limitations.

It has 8 PIDs (called by temp ranges or Dig In) and a perfect AutoTune function. You can also buy software for it to configure, save configurations, and monitor/trend operation.

I have a bad taste for running PID in ladder logic. It always has limitations.

Peter Nachtwey

Member

I asked about the possibilities of varying load in post #3 and now we finally get the full picture?

Michaeli, what temperature do you want to control? Then temperature when the widgets are under the sensor or the temperature between the widgets? You can't control both because the system can't react that fast. The parts are going by every 18 seconds. The time constants are longer than that. You will not be able to keep the temperature constant within 2-3 degrees. You may be able to keep the temperature when the widgets are under the temperature sensor constant if you only activate the PID during the time when the widgets are under the sensor or have a way of measuring only the temperature of the widgets.

Some engineer really screwed this up.

There are thermal cameras that can measure the temperature of the widgets and only the widgets. The temperature of the widgets shouldn't change quickly.

Michaeli, what temperature do you want to control? Then temperature when the widgets are under the sensor or the temperature between the widgets? You can't control both because the system can't react that fast. The parts are going by every 18 seconds. The time constants are longer than that. You will not be able to keep the temperature constant within 2-3 degrees. You may be able to keep the temperature when the widgets are under the temperature sensor constant if you only activate the PID during the time when the widgets are under the sensor or have a way of measuring only the temperature of the widgets.

Some engineer really screwed this up.

There are thermal cameras that can measure the temperature of the widgets and only the widgets. The temperature of the widgets shouldn't change quickly.

I would recomend to have the first 3 zones running with a fan, to get faster response, It is impossible to control in 18 seconds, so you will need a stabilizer (like a few iron blocks in the oven.

Maybe it is better to have a expert control on it, it will react on each condenser apart, and have better line control.

Maybe it is better to have a expert control on it, it will react on each condenser apart, and have better line control.

Peter Nachtwey

Member

This application requires a rethink.

A thermal camera would detect the temperature of the individual widgets.

It is clear that more heat will be required as the piece rate through the oven increases. Some sort of feed forward will be needed so there is an output term proportional to the rate of widgets going through the oven.

This should be easy but you can't control what you don't understand.

While I agree iron blocks would stabilize the detected temperature some it isn't the solution to the problem IF the goal is to control the temperature of the widgets.I would recomend to have the first 3 zones running with a fan, to get faster response, It is impossible to control in 18 seconds, so you will need a stabilizer (like a few iron blocks in the oven.

A thermal camera would detect the temperature of the individual widgets.

The control will be easy or easier once the Michaeli can measure what he is trying to control.Maybe it is better to have a expert control on it, it will react on each condenser apart, and have better line control.

It is clear that more heat will be required as the piece rate through the oven increases. Some sort of feed forward will be needed so there is an output term proportional to the rate of widgets going through the oven.

This should be easy but you can't control what you don't understand.

Similar Topics

Hello, I am attempting to tune a PID loop on a process. The process involves a valve with electronic actuator that has quite a high deadband...

- Replies

- 10

- Views

- 2,199

so i have 4 25gpm wells feeding a 1000gal tank (T-1), with an additional 15gpm from a decant tank for 3hrs every 12hrs.

P1 and P2 both controlled...

- Replies

- 154

- Views

- 35,938

Hi everyone, yet another PID problem. I'm hoping I understand enough of the process I'm controlling that my request for help is reasonable. If a...

- Replies

- 113

- Views

- 28,243

A few months ago, I started to look into PID controllers and the tuning of first order processes. This has, partly thanks to you, resulted in a...

- Replies

- 162

- Views

- 62,594

I haven't had to tune a PID loop in a very long time.

It's actually a PI loop for a pulse width modulation s.v.

What was the name of that tuning...

- Replies

- 16

- Views

- 4,122