drbitboy

Lifetime Supporting Member

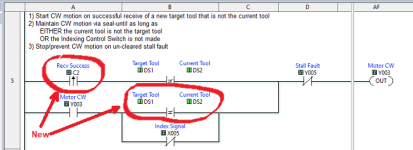

The solenoid should go low when the turret locks. After the CCW motion. Its staying energized.

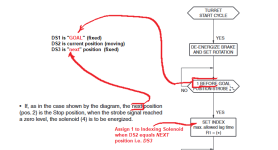

My Rung 10 will leave the [4 Indexing Solenoid Y001] output's value a 1 (energized), but then it should be de-energized when BOTH the brake engages (Y002 becomes 0) AND the Post-CCW timer (Time delay "T2" in the manual) expires.

Last edited: