HI all, I got some great help my last post here I hope this one goes as well. I am having a problem getting a Banner light to turn on. The light is a Dome light,with a part number of K50LGRYA120Q. I am using the AB SLC 500 platform, an SLC 5/04, 10 slot rack and have the light connected to a 1746-OW16 output card. I believe my problem is that the light is an LED light and the output card is a relay output card. Changing the card is not an option and the rack is full. If I toggel the output the light comes on, so I know the light is good and the output works. Does anyone know of a way to make this setup work? I suppose I could mount a relay and turn it on and off but the panel is allready crowded and quite messy to begin with, I really don't want to add anymore relays to it. The logic line up to the output is all working as it should, but when true the output refuses to turn on. I swappd out the card and this did not help. Any help would be greatly appreciated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Problem with 1746-OW16 and Banner light

- Thread starter paulrae

- Start date

sthompson

Lifetime Supporting Member + Moderator

The OW16 isn't an issue unless the you have the wrong voltage for the light, which it doesn't sound like in this case. You probably have the Output Coil in your program twice, or it is being reset in some other fashion before the Output Table is updated. The best thing to do is post your Program File (Zip it first), and let us have a look at your PLC Code.

Stu......

Stu......

Not necessarily a good assumption, Stu. That OW16 does NOT necessarily have to be switching 120. It can just as easily switch 24VDC, then we know that light won't work.

Paul, you say when you toggle the output, the light comes on. I assume you mean the output indicator on the module itself, right? Check to see if you're really getting output voltage on the output. The module indicator is really in the circuit before the relay itself and is not a good indication that the output really is coming on. If the output indicator is not coming on, then you have a programming issue - most likely a duplicated coil, or unscanned logic, or ...

Also, what is your output voltage?

Finally, how are you hooking up the Banner light -- it should work fine if it's being connected to 120. Does it work when you connect it to something you know is "hot"?

Paul, you say when you toggle the output, the light comes on. I assume you mean the output indicator on the module itself, right? Check to see if you're really getting output voltage on the output. The module indicator is really in the circuit before the relay itself and is not a good indication that the output really is coming on. If the output indicator is not coming on, then you have a programming issue - most likely a duplicated coil, or unscanned logic, or ...

Also, what is your output voltage?

Finally, how are you hooking up the Banner light -- it should work fine if it's being connected to 120. Does it work when you connect it to something you know is "hot"?

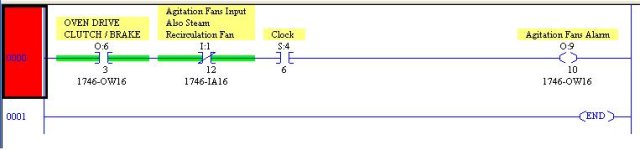

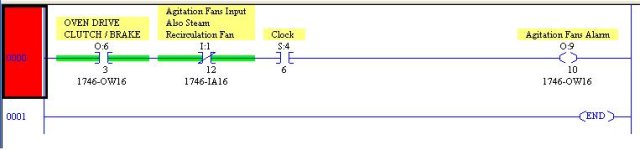

The portion of the program in question is ladder 3 Agitation. I have searched for the output assigned to the Banner light and cannot find it used anywhere else in the program. When I toggle the output, the output indicator lamp comes on and the Banner light comes on. That fact tells me that the output is operational and the voltage to the Banner light must be correct. I actually did measure the voltage to the card and I measure 110 VAC at both card connections. (actual measurement 108 VAC)The rest of the outputs on that card are activating 110 VAC coils and indicator lights and they all operate correctly.I even removed the 1 second flasher to see if that was the issue and got the same results.

Attachments

OkiePC

Lifetime Supporting Member

Yes, you need to add a JSR 3 somewhere in LAD 2.

Thanks OKI

That thought just occured to me aftr remembering having seen the JSR instruction in other programs. I am now beginning to understand how it is used. Is there a good tutorial that you know of that explains the usaged ? Also I have included a zip file of the modified program. I am wondering about the S:34/3 and S:34/4 OTE instructions in ladder 2. I copied this from one of the programs I had to troubleshoot in the past and really do not understand what they do, the program came from a machine system that was built and programmed in Canada by AMF.

That thought just occured to me aftr remembering having seen the JSR instruction in other programs. I am now beginning to understand how it is used. Is there a good tutorial that you know of that explains the usaged ? Also I have included a zip file of the modified program. I am wondering about the S:34/3 and S:34/4 OTE instructions in ladder 2. I copied this from one of the programs I had to troubleshoot in the past and really do not understand what they do, the program came from a machine system that was built and programmed in Canada by AMF.

Mickey

Lifetime Supporting Member

Your JSR instruction for ladder three needs to be in Ladder 2. And unless there is a reason to run ladder 4 after ladder 3 then the JSR instruction for ladder 4 can also be in ladder 2. See online instruction help for info in the "JSR" instruction.

Last edited:

Mickey

Lifetime Supporting Member

See PDF below for info about the S:34/3 and S:34/4 status bits.

Problem with 1746_OW16 and Banner Light

Thanks for pointing that out. That is what I thought I was doing. Take alook at the attached, I think it will work now. This is a fast learning curve for me, I am used to simply using the programs to troubleshoot the machine procesess the PLC's control. Modifying and programming them is interesting, but there sure is a lot to learn and remember.

Thanks for pointing that out. That is what I thought I was doing. Take alook at the attached, I think it will work now. This is a fast learning curve for me, I am used to simply using the programs to troubleshoot the machine procesess the PLC's control. Modifying and programming them is interesting, but there sure is a lot to learn and remember.

Mickey

Lifetime Supporting Member

That should work.

Mickey

Lifetime Supporting Member

Hi All

Sorry this took so long, but the modifications worked just as expected.

Thanks again

Good to hear, and thanks for coming back to let the forum know.

Similar Topics

I have a machine I'm trying to refurbish. Currently, it won't home without intervention. It's using a 1746-L532 processor with two 1746-HSRV SLC...

- Replies

- 0

- Views

- 1,223

Hello,

I have 3 of the same valve positioners controlling V-Ported valves to control the flow of our product with a user input.

Their wiring...

- Replies

- 7

- Views

- 1,915

I've experiencing problems regarding the decimal equivalent to mA reading of each channel.

Based on 1746 NO4I manual, the equivalents are:

1...

- Replies

- 1

- Views

- 2,095

I have an SLC 5/03 with I/Os in one of our machine. I am facing a problem with an Allen Bradley PLC Input card 1746-IA16 (85-132VAC) that voltage...

- Replies

- 5

- Views

- 2,942

Replacing a PLC with a SLC 500, we had a problem with a 1746-OB16. During checkout we found a loose wire on the DC comm to this card, once lifted...

- Replies

- 3

- Views

- 2,500