dalporto

Lifetime Supporting Member

Hi.

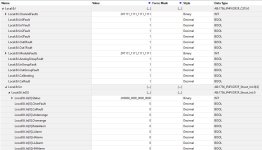

Which of these system bits should I use to know that a particular AI or AO channel is faulted? Like I lost the 4-20mA loop, or the input is busted only on that particular input.

The screenshot comes from a live PLC without that card installed.

So, Local:8:I.In0Fault looks like it's kind doing its job, while Local:8:I.In[0].ChanFault is not, probably because the module isn't actually there.

I cannot find the difference between both of them, so right now I'm just using both.

Which ones are you using?

Thanks.

Which of these system bits should I use to know that a particular AI or AO channel is faulted? Like I lost the 4-20mA loop, or the input is busted only on that particular input.

The screenshot comes from a live PLC without that card installed.

So, Local:8:I.In0Fault looks like it's kind doing its job, while Local:8:I.In[0].ChanFault is not, probably because the module isn't actually there.

I cannot find the difference between both of them, so right now I'm just using both.

Which ones are you using?

Thanks.