dalporto

Lifetime Supporting Member

Hi.

Not the fist time I'm saying this but just to give a background.

95% of my PLC programming has used Schneider over the last 10 years on the same kind of process, so I'm struggling with Logix Designer right now trying to implement the same kind of logix so the customers and other technicians / engineers aren't too lost in the code.

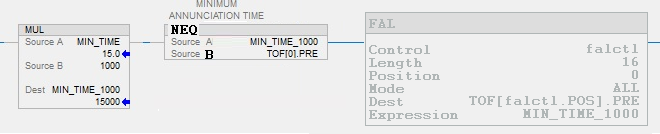

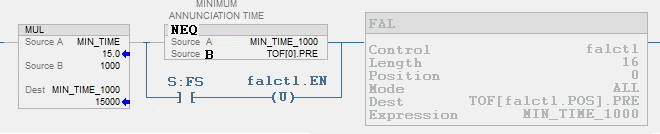

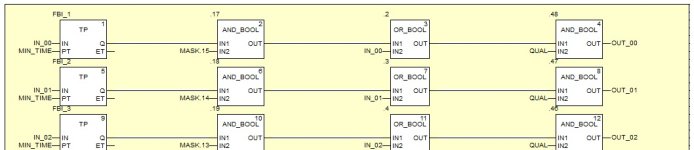

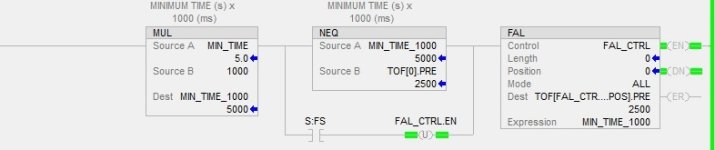

On an Add-On block in LD, I have 16 different inputs and 16 related outputs. There is a TOF for each of them on their respective rungs that I put in an array to save time, but they're all using the same value coming from an input on the block, first one would be TOF[0].

I just want to move my input value to all 16 of the TOF.PRE and I just cannot find a way to do it. I could have 16 lines to write the value in the 16 TOF.PRE but I'm still hoping that Rockwell planned for that at some point.

With Schneider I would just have used the same tag on all rows with a different input, but RSLogix made sure that we needed to use a "different" timer each time.

Thanks.

Not the fist time I'm saying this but just to give a background.

95% of my PLC programming has used Schneider over the last 10 years on the same kind of process, so I'm struggling with Logix Designer right now trying to implement the same kind of logix so the customers and other technicians / engineers aren't too lost in the code.

On an Add-On block in LD, I have 16 different inputs and 16 related outputs. There is a TOF for each of them on their respective rungs that I put in an array to save time, but they're all using the same value coming from an input on the block, first one would be TOF[0].

I just want to move my input value to all 16 of the TOF.PRE and I just cannot find a way to do it. I could have 16 lines to write the value in the 16 TOF.PRE but I'm still hoping that Rockwell planned for that at some point.

With Schneider I would just have used the same tag on all rows with a different input, but RSLogix made sure that we needed to use a "different" timer each time.

Thanks.