dalporto

Lifetime Supporting Member

Hi.

I'll say it again, I worked mostly with Unity Pro for the last 12 years and I'm trying to convert our FBD standard to Rockwell Logix Designer to make it look as much as possible as the "original" so our technicians knows what they are looking at when on site. Customer really wants a Rockwell PLC even if it 3 times the price and not really better for that application.

Anyway, I hit another bump today.

You can first look at the scratch of my AOI here:https://ibb.co/MMtxKnp

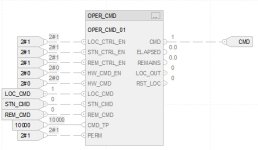

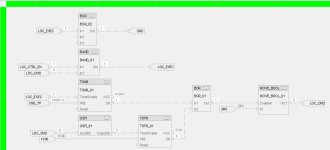

First you have the MOVE_BOOL AOI (bottom) that I created. If System EnableIn is true, it will pass the IN to the OUT. If disabled, it will stay in the last state.

At the top I have LOC/STN/REM_CMD as inputs, which represents BOOL commands coming either from three distincts HMI/SCADA. Up to now I'm trying to just have the LOC_CMD working, so the block isn't completed, I should have a reset and a MOVE_BOOL for each CTRL Authority.

So let say I have a Local HMI sending a command to LOC_CMD given that LOC_CTRL_EN is true, I'm gonna pulse the CMD Output for the CMD_TP duration (2.5 sec here). Most circuits are built that way: PLC output---2-3 second command to 24VDC relay----relay pulse into start / stop XV circuit in parallel of the start/stop buttons. This is why I don't latch.

After Timer.DN of 2.5 seconds, I want the block to force the LOC_CMD back to FALSE (so I could send the command again), so I pick RST_LOC, which should send a "0" to LOC_CMD by enabling the MOVE_BOOL block at the bottom.

But what is happening right now is that even if the MOVE_BOOL block is not enabled and LOC_CMD is "0", LOC_CMD still forces the input to stay false, which is a big difference with what I'm accustomed to with Unity Pro. This is why I added the MOVE_BOOL with the expectation that the scan order would take care of the issue after I have tried to manage it inside the block with the same result.

Does someone knows a way how I could reset that input to zero from within or with minimal effort? Or does someone have another idea on how to build that?

Thanks.

I'll say it again, I worked mostly with Unity Pro for the last 12 years and I'm trying to convert our FBD standard to Rockwell Logix Designer to make it look as much as possible as the "original" so our technicians knows what they are looking at when on site. Customer really wants a Rockwell PLC even if it 3 times the price and not really better for that application.

Anyway, I hit another bump today.

You can first look at the scratch of my AOI here:https://ibb.co/MMtxKnp

First you have the MOVE_BOOL AOI (bottom) that I created. If System EnableIn is true, it will pass the IN to the OUT. If disabled, it will stay in the last state.

At the top I have LOC/STN/REM_CMD as inputs, which represents BOOL commands coming either from three distincts HMI/SCADA. Up to now I'm trying to just have the LOC_CMD working, so the block isn't completed, I should have a reset and a MOVE_BOOL for each CTRL Authority.

So let say I have a Local HMI sending a command to LOC_CMD given that LOC_CTRL_EN is true, I'm gonna pulse the CMD Output for the CMD_TP duration (2.5 sec here). Most circuits are built that way: PLC output---2-3 second command to 24VDC relay----relay pulse into start / stop XV circuit in parallel of the start/stop buttons. This is why I don't latch.

After Timer.DN of 2.5 seconds, I want the block to force the LOC_CMD back to FALSE (so I could send the command again), so I pick RST_LOC, which should send a "0" to LOC_CMD by enabling the MOVE_BOOL block at the bottom.

But what is happening right now is that even if the MOVE_BOOL block is not enabled and LOC_CMD is "0", LOC_CMD still forces the input to stay false, which is a big difference with what I'm accustomed to with Unity Pro. This is why I added the MOVE_BOOL with the expectation that the scan order would take care of the issue after I have tried to manage it inside the block with the same result.

Does someone knows a way how I could reset that input to zero from within or with minimal effort? Or does someone have another idea on how to build that?

Thanks.