Watched this with a smile , Cannot believe the short sighted vision of RSL.

Many IDE's can have an array of timers with Time values stored in a variable

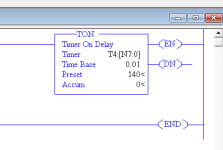

The code below shows a typical way of using a timer where the preset is a common variable not a fixed value & each timer can be referenced as an array of timers. So it is possible to either have a global variable for the PRE or even create an array of PRE & do a fill move so that all the timers PRE can be set to what ever time is required.

Many IDE's can have an array of timers with Time values stored in a variable

The code below shows a typical way of using a timer where the preset is a common variable not a fixed value & each timer can be referenced as an array of timers. So it is possible to either have a global variable for the PRE or even create an array of PRE & do a fill move so that all the timers PRE can be set to what ever time is required.