Akbrewer

Member

Hello!

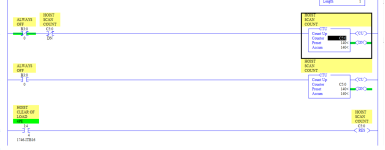

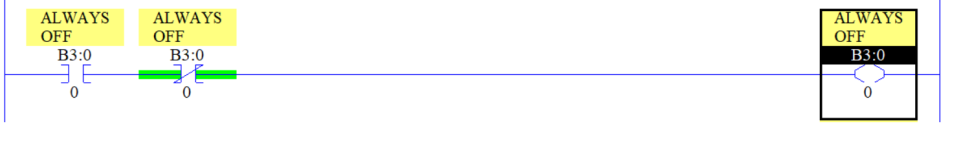

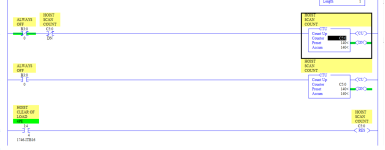

I have a question about a routine I found on one of our box palletizing machines. I've attached the 3 rungs that I have the question about, this is using Rockwell RS500 on a 5/04 processor.

I'm trying to figure out how the C:5 scan counter works, it uses an always off bit being false on one rung and true on the next rung, these two rungs will increment the counter as long as the counter hasn't finished. I'm assuming this is basically using the PLC scan time to run up the counter? I'm still trying to wrap my head around how an "always off" bit is ever actually active, but it seems to work and has been on this machine for years this way.

This C:5 counter is being used as a high speed counter to stop a motor at a specific position. I found today that after I added some additional program instructions to this PLC and another output card to the PLC that the position of the motor stopping point has changed. I'm assuming its because the scan time of the processor changed because it has more actions to compute and control?

Is there a more repeatable way to set up this counter without having to rely on the processor scan times not changing? I thought about trying to use the S: system time to do this process but just wanted to see what anyone else thought about this.

Thanks for any ideas.

I have a question about a routine I found on one of our box palletizing machines. I've attached the 3 rungs that I have the question about, this is using Rockwell RS500 on a 5/04 processor.

I'm trying to figure out how the C:5 scan counter works, it uses an always off bit being false on one rung and true on the next rung, these two rungs will increment the counter as long as the counter hasn't finished. I'm assuming this is basically using the PLC scan time to run up the counter? I'm still trying to wrap my head around how an "always off" bit is ever actually active, but it seems to work and has been on this machine for years this way.

This C:5 counter is being used as a high speed counter to stop a motor at a specific position. I found today that after I added some additional program instructions to this PLC and another output card to the PLC that the position of the motor stopping point has changed. I'm assuming its because the scan time of the processor changed because it has more actions to compute and control?

Is there a more repeatable way to set up this counter without having to rely on the processor scan times not changing? I thought about trying to use the S: system time to do this process but just wanted to see what anyone else thought about this.

Thanks for any ideas.