ZestyMozzarella

Lifetime Supporting Member

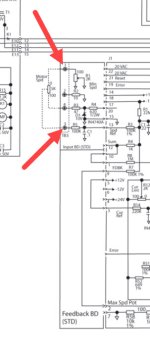

I have a conundrum with this current circuit. I have a Siemens 1215C AC/DC/Relay and an old drive - Ratiotrol (now Boston Gear company I believe), VEL/VEH 150 model. It has a potentiometer for speed I decided to hijack because I want HMI controls for it.

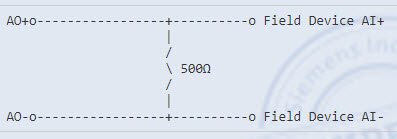

My 1215C has two analog outputs. I put them across a 500Ohm resistor pack and put a 0-10VDC signal on the COM and Wiper of the old POT location. It scales just fine 0-10VDC like the POT provided. Issue being...the drive and motor runs at 7FPM when it's a 25FPM drive maximum. Since I hijacked the location, the 0-10VDC signal I can see full scale on my meter coming from the PLC feeding the same area the POT did. I figured some kind of noise or issue was present in the signal, so...

I put a signal isolator (random old one as well) in the line. This improved the situation. Still 0-10VDC scaling IN and OUT of the isolator. Now the drive scales from 0-12 FPM but not the full range...annoying.

Theoretically in my mind, I can see the same 0-10VDC the old POT provided yet the full drive scale doesn't appear and I cannot figure out why that would be....shouldn't be any different. The only thing I can think of is perhaps the older drives need a higher current source than what the PLC or the Isolator can provide for the full range? This old Ratiotrol drive feeds a 180VDC Arm, 7.7 Amps, 1.5 HP, 1750 RPM DC motor.

Does anyone have any idea why this might be? My isolator is powered on 24 VDC but the supply is a 5A and not being pushed to max, I was thinking I could up it to a 10A but I don't think that matters here. The only thing I can think of is some kind of loop issue perhaps. These old drives have poor grounding and are hard to find schematics on. I'm thinking I should just upgrade the drive to a KB Electronics or GSD8-120-10N Automation Direct drive of sorts with an analog control module.

I'm open to ideas of getting this working sooner than sourcing new equipment though if anyone has any thoughts? Thanks!

My 1215C has two analog outputs. I put them across a 500Ohm resistor pack and put a 0-10VDC signal on the COM and Wiper of the old POT location. It scales just fine 0-10VDC like the POT provided. Issue being...the drive and motor runs at 7FPM when it's a 25FPM drive maximum. Since I hijacked the location, the 0-10VDC signal I can see full scale on my meter coming from the PLC feeding the same area the POT did. I figured some kind of noise or issue was present in the signal, so...

I put a signal isolator (random old one as well) in the line. This improved the situation. Still 0-10VDC scaling IN and OUT of the isolator. Now the drive scales from 0-12 FPM but not the full range...annoying.

Theoretically in my mind, I can see the same 0-10VDC the old POT provided yet the full drive scale doesn't appear and I cannot figure out why that would be....shouldn't be any different. The only thing I can think of is perhaps the older drives need a higher current source than what the PLC or the Isolator can provide for the full range? This old Ratiotrol drive feeds a 180VDC Arm, 7.7 Amps, 1.5 HP, 1750 RPM DC motor.

Does anyone have any idea why this might be? My isolator is powered on 24 VDC but the supply is a 5A and not being pushed to max, I was thinking I could up it to a 10A but I don't think that matters here. The only thing I can think of is some kind of loop issue perhaps. These old drives have poor grounding and are hard to find schematics on. I'm thinking I should just upgrade the drive to a KB Electronics or GSD8-120-10N Automation Direct drive of sorts with an analog control module.

I'm open to ideas of getting this working sooner than sourcing new equipment though if anyone has any thoughts? Thanks!