rQx

Lifetime Supporting Member

Hi,

I'm no expert in PID regulating so I need some advise.

I have a VFD controlled deepwaterpump that is maintaining the pressure in a closed pipe system. There is a valve that is opening when water is needed and closes when here is no need for water. This valve open and close relatively slow.

The Siemens LOGO has only P and I functionality.

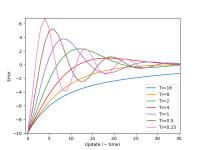

As it is I have my P set to 0.6 and I set to 0.3s, this is working pretty good.

When filling my pipes when the valves are closed there is a overshoot, SP is 8Bar and it goes to 10Bar before going down again.

During normal operation when the valve is open the SP is maintained pretty good around the SP. +/- 0,2Bar (the sensor is a little bit up and down, it seems to be interference from the pump)

My problem is that I wan't to limit the overshoot to protect the pipes. But I can't increase the P because then the SP will be fluctuating to mush during normal operation.

I can't change the P and I during operation (due to limits in the Siemens LOGO). I have thought of a solution of using two PI regulator blocks and running them in parallell. One that is fast and one that is slow. The fast one would be active all the time unless the SP is within +/- 0,5Bar of the SP. Would this be a somewhat good solution or has anyone any better?

I'm no expert in PID regulating so I need some advise.

I have a VFD controlled deepwaterpump that is maintaining the pressure in a closed pipe system. There is a valve that is opening when water is needed and closes when here is no need for water. This valve open and close relatively slow.

The Siemens LOGO has only P and I functionality.

As it is I have my P set to 0.6 and I set to 0.3s, this is working pretty good.

When filling my pipes when the valves are closed there is a overshoot, SP is 8Bar and it goes to 10Bar before going down again.

During normal operation when the valve is open the SP is maintained pretty good around the SP. +/- 0,2Bar (the sensor is a little bit up and down, it seems to be interference from the pump)

My problem is that I wan't to limit the overshoot to protect the pipes. But I can't increase the P because then the SP will be fluctuating to mush during normal operation.

I can't change the P and I during operation (due to limits in the Siemens LOGO). I have thought of a solution of using two PI regulator blocks and running them in parallell. One that is fast and one that is slow. The fast one would be active all the time unless the SP is within +/- 0,5Bar of the SP. Would this be a somewhat good solution or has anyone any better?