Mas01

Member

See the attached image.

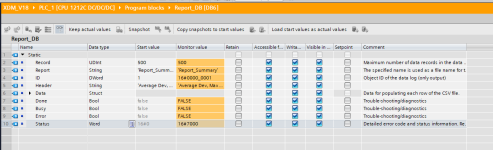

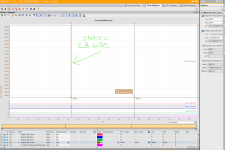

The Datalog should be created when I press Report_Button_Pressed on the HMI.

This image is taken when I pressed the button with my finger (left index finger, before you ask).

Does anyone know why the output (DONE) from DataLogCreate is FALSE.

AFAIK, the DONE is only TRUE for one cycle, but that should be enough to set the flag that I have circled. Anyone know why this flag is FALSE?

Thanks

The Datalog should be created when I press Report_Button_Pressed on the HMI.

This image is taken when I pressed the button with my finger (left index finger, before you ask).

Does anyone know why the output (DONE) from DataLogCreate is FALSE.

AFAIK, the DONE is only TRUE for one cycle, but that should be enough to set the flag that I have circled. Anyone know why this flag is FALSE?

Thanks