Mas01

Member

I'm making a meal of this, my brain's not in gear.

Also, I'm new to S7 TIA/WinCC so excuse my ignorance...

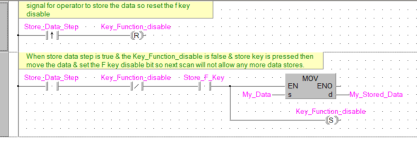

See redacted pic.

Pressing F7 (SAVE icon) causes the values (mm) in the big boxes to be corrected by adding a correction factor, and that value gets displayed in the small box underneath it. - see pic

That works fine - but as it stands, the operator can keep pressing F7 and the correction factor will be applied again and again and again...which is not what I want. It needs to be a one-shot SAVE.

After the first press of F7, I want:

"STORE ZEROED VALUES" to change to "SAVED"

SAVE icon to disappear

F7 function to be disabled (so further saves are not possible)

Can anyone help?

Happy to expand on the above if unclear.

Thanks

p.s. the Event Release key is just the 'Resetbit' of the Press key.

Also, I'm new to S7 TIA/WinCC so excuse my ignorance...

See redacted pic.

Pressing F7 (SAVE icon) causes the values (mm) in the big boxes to be corrected by adding a correction factor, and that value gets displayed in the small box underneath it. - see pic

That works fine - but as it stands, the operator can keep pressing F7 and the correction factor will be applied again and again and again...which is not what I want. It needs to be a one-shot SAVE.

After the first press of F7, I want:

"STORE ZEROED VALUES" to change to "SAVED"

SAVE icon to disappear

F7 function to be disabled (so further saves are not possible)

Can anyone help?

Happy to expand on the above if unclear.

Thanks

p.s. the Event Release key is just the 'Resetbit' of the Press key.

Last edited: