BachPhi

Member

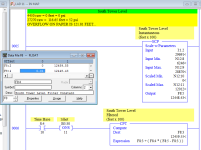

I use Mickeys method a lot. I have found that I need to condition the frequency of the filtering to slow it down a bit. I often precede the filter math with a bit from the free running clock and a oneshot.

On a side note, the free running clock is much faster in a Micrologix 1400 than it is in a SLC 5/03. I might use the bit S:4/4 or 5 in a SLC to update the filter every 320 or 640ms, but in the Micrologix I end up using bit 10 or 11. I could just set the filter number to a ridiculously small value and let it run as fast as it can, but I prefer the filter logic to be consistent regardless of scan time by triggering it with a timer or timebase I can control.

May I see a little bit of that codes you are talking about.