Bobobodopalus

Member

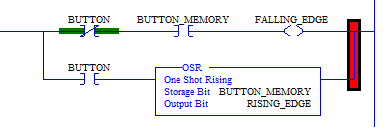

Just wondering if i can make my code look a little nicer and sharing storage bits like below

https://imgur.com/a/SMNxOPu

does this work or does it need separate storage?

https://imgur.com/a/SMNxOPu

does this work or does it need separate storage?

Last edited: