Hello all,

PLC-programming noob here.

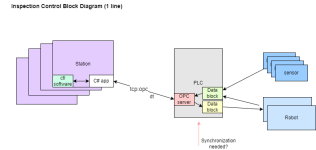

I have multiple clients accessing some data on my Siemens S7 1211C PLC; some OPC clients and some direct (IE).

To avoid potential race conditions I want to synchronize their access using a lock. How does one do that on a PLC?

The OPC server I am using is the integrated OPC server on the S7-1200.

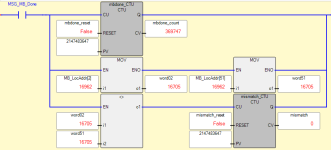

EDIT: looking at https://www.reddit.com/r/PLC/comments/jj3ab6/siemens_s7_with_wincc_oa_hmi_newbie_question/ , I see that the PLC code really only needs to buffer the inputs from the HMI at scan start time, and use only those values. I think this can work, right?

Much thanks.

z

PLC-programming noob here.

I have multiple clients accessing some data on my Siemens S7 1211C PLC; some OPC clients and some direct (IE).

To avoid potential race conditions I want to synchronize their access using a lock. How does one do that on a PLC?

The OPC server I am using is the integrated OPC server on the S7-1200.

EDIT: looking at https://www.reddit.com/r/PLC/comments/jj3ab6/siemens_s7_with_wincc_oa_hmi_newbie_question/ , I see that the PLC code really only needs to buffer the inputs from the HMI at scan start time, and use only those values. I think this can work, right?

Much thanks.

z

Last edited: