KonstantinKolev

Member

Hi,

For some time I have been struggling with establishing a MODBUS RTU communication between WAGO PFC200 750-8212 and a Sentera ACT-125-H damper valve for ventilation.

Damper Valve

Here is some info about the damper valve - it has input and holding register that are all unsigned integer (UINT) datatype. The following settings are used with respect to the MODBUS RTU - 9600 baudrate, 8 data bits, even parity, 1 stop bit.

Let me explain the wiring setup - from the controller enclosure one cable goes to the first damper valve and all the following damper valves are daisy chained. The cable is shielded with 4 cores - 24V DC and MODBUS RTU signals.

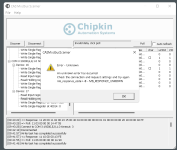

In the WAGO there is always a "response timeout error" and no information is read even though I only read one (1) holding register.

What I have tried is to calculate the time between the frames and the the between the characters in the frame. I got values in the milliseconds (ms) range and entered the values in the MODBUS RTU Master settings but the result is the same.

The damper valves work with a FATEK controller without any problem, they also work with a MODBUS to USB converter and a MODBUS Scanner program.

Another thing that I tried is to sniff what the WAGO and the damper valve send to each other. I used a MODBUS to USB converter connected in parallel to the WAGO. It seems that the WAGO is polling the correct date but the damper valves responds not what is expected. I compared the data with the data I sniffed from the setup with the FATEK controller and the MODBUS Scanner.

What would you suggest to do to investigate the problem further and hopefully find a way to resolve the problem?

Best Regards

Konstantin Kolev

For some time I have been struggling with establishing a MODBUS RTU communication between WAGO PFC200 750-8212 and a Sentera ACT-125-H damper valve for ventilation.

Damper Valve

Here is some info about the damper valve - it has input and holding register that are all unsigned integer (UINT) datatype. The following settings are used with respect to the MODBUS RTU - 9600 baudrate, 8 data bits, even parity, 1 stop bit.

Let me explain the wiring setup - from the controller enclosure one cable goes to the first damper valve and all the following damper valves are daisy chained. The cable is shielded with 4 cores - 24V DC and MODBUS RTU signals.

In the WAGO there is always a "response timeout error" and no information is read even though I only read one (1) holding register.

What I have tried is to calculate the time between the frames and the the between the characters in the frame. I got values in the milliseconds (ms) range and entered the values in the MODBUS RTU Master settings but the result is the same.

The damper valves work with a FATEK controller without any problem, they also work with a MODBUS to USB converter and a MODBUS Scanner program.

Another thing that I tried is to sniff what the WAGO and the damper valve send to each other. I used a MODBUS to USB converter connected in parallel to the WAGO. It seems that the WAGO is polling the correct date but the damper valves responds not what is expected. I compared the data with the data I sniffed from the setup with the FATEK controller and the MODBUS Scanner.

What would you suggest to do to investigate the problem further and hopefully find a way to resolve the problem?

Best Regards

Konstantin Kolev

Last edited: