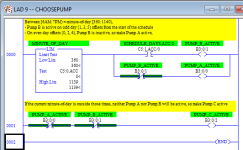

Hey guys, thanks for reading. I am trying to use a micrologix(1000 or1500) to control 3 hydraulic pumps. I have a time clock to give a signal to the plc and a rotary switch to set schedules. At 6am pump A or B will turn till 7pm then pump C turns on. A and B need to alternate days. Then I need 3 schedules 4day, 5day, and 6day. I am thinking a counter to reset every 7 days. Time clock on 6am-7pm will give one count per day. XIO, XIC the same input to turn pumps on or off but how to alternate pumps A/B with counter? Examine accumulated number? Don't know how to do that. Then set a rotary switch to set schedule.

Example schedule 1= 4days.Timeclock turns on Count 1 turns on pump A. Loose time clock signal Pump A off Pump C on. Next day time clock on, count 2 pump B on. Loose time clock signal pump C on. Rinse repeat 4 days.3 days pump C on. Cycle starts over. Is this doable?

Example schedule 1= 4days.Timeclock turns on Count 1 turns on pump A. Loose time clock signal Pump A off Pump C on. Next day time clock on, count 2 pump B on. Loose time clock signal pump C on. Rinse repeat 4 days.3 days pump C on. Cycle starts over. Is this doable?