Manglemender

Member

Peter,

Thanks for taking the time and effort to share some of your insights with the forum.

Nick

Thanks for taking the time and effort to share some of your insights with the forum.

Nick

I have made videos but they are product based and I like to make them in HD quality, about 1280x800. I can make youtube videos but youtube doesn't have the resolution that I like. I want people to be able to clearly see the numbers on the screen. If I made a youtube video I would need to make extensive use of the zoom in and out feature.PLCRookie said:I think you should do a series and post it on youtube.

No, my response is above. It will probably be read here as much as in control engineering magazine.kdcui said:Peter,

Have you considered writing in to Control Engineering in response to that article?

You responses definitely merit at least a small column.

Why not simply use more P gain?Bill Wheeler said:Great Thread!

The Integral term is the most effective parameter in being able to enhance P-only control to achieve a faster "stable" response to a SP/PV error.

What about the mass on the spring?For most process control applications where there is minimal "latent energy" in the system you should find PI control to be sufficient.

Again, what about the mass on the spring?It is true that using the D-term will have little to no positive impact in a process where there is a minimal (and repeatable) time lag between when a CV output change is made and the "full" PV response is achieved.

???It is also true that the use of the D-Term is ineffective when the SP/PV error can change directions within a few controller scans.

The D-Term is very effective for processes where there is a significant amount of "latent energy" or “mechanical inertia” in the controlling system (i.e. heaters and mechanical motion) or when the process is very sensitive to SP overshoot.

It depends upon the number of poles. You totally ignored or misinterpreted what I said.

This is what happens when the mechanical designers save a few buck on the valves and waste far more in the control guys time plus the fact the system will never run as well as it could and this costs money every minute.I know that I have spent hours of frustration trying to tune a loop where the control application used a poorly sized centrifugal pump or ball valve as the controlling device. In these examples the ratio of PV response to a CV change is not very linear from a 0 to 100% CV output - a 10 point increase to CV output when the current CV is at 10 will not achieve the same magnitude of PV change as when the 10 point change occurs when the current CV is at 50. There are many "advanced" PID controllers that can use a multitude of different "fuzzy logic" approaches to overcome the failings of the "simple" PID controller. The rule must be – KNOW YOUR

I am actually working on an auto tuning for non-linear valves now.

Always use some form of chart recorder when tuning a PID loop. At the very least chart the PV. I have also found tracking the CV to be helpful when coming in blind to a new process. The PV response curve is the only way to gage the effectiveness of a PID Term change. I find it utterly impossible to optimize a PID loop without the chart recorder.[/FONT]

Yes, but one should graph both PV AND the CV. Then one can calculate the PV as a function of CV which is the first step to auto tuning.

How?Decide what type of control is most appropriate for the application, P, PI, PD, PID, or Advanced PID.

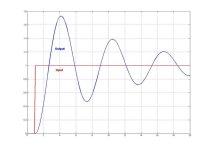

These are the kind of statements I object to. I am very disappointed because what I said above was not understood.Always start tuning with the P-Term while the other parameters are set to a minimum number. The typical response for P-Only control will be a periodic oscillation above and below SP when the P-Term is too large or a failure to reach SP when the P-Term is too low. I have found the optimum P value to be the point at which the 1st sign of oscillation is seen.

Again, think of the mass on the spring. It will oscillate on its own and adding any P gain will make it worse. There is no or little damping!!!!! So what would you add first???? Please say derivative gain.

I object to Bill Wheeler's post for the same reason I objected to the Control Engineering article. There are too many statements that aren't qualified.

BTW, don't think the mass on the spring is unrealistic. Hydraulic systems can be roughly modeled as a mass between two springs. Sure there is a little friction but that is often the problem. There is only a little friction relative to the mass so the damping factor is quite low.

Another example is a small DC motor in torque control with a mass spinning freely on the end of the shaft. I have such a system. The damping on this system is quite low because the mass is large compared the friction. If I turned up the P gain a little it will oscillate without stopping. I like to demonstrate the effect of the derivative gain by turning all gains off and letting the students turn the shaft. They find it turns and spins freely. Then as I increase the derivative gain ONLY the students can feel the effect. It is like some is in grabbing the shaft and trying to keep it from turning. Eventually the D term is up so high that the quantizing effects do to the low resolution make the turning feel rough instead of smooth. At this point the derivative gain is too high and it should be backed off. Now one can increase the P gain to very high levels. The P gain can be increased to MUCH higher than if one simply adjusts the P gain first until it oscillates without the derivative gain.

I am not making this stuff up. This is not an opinion or something that I am repeating from someone else and without proof. I have hundreds of Mathcad files showing how to tune many different types of systems many different types of ways and showing the response. I have proof and the math to back it up. I have enough examples where it is easy for me to find examples that are "exceptions" like the mass on a spring.

There are too many beans catch them all without knowing Laplace transforms and having a good CAS ( computer algebra system ) like wxMaxima. Matlab or Scilab would help too. It took me many years to learn.Hello i am knew to the forums but Mr Nachtwey moved me enough to say sir your words have meaning and conviction. I relize now i no so little about this subject respect Mr Nachtway

ps any time you want to spill the beans on PID Loop I will listen

Sure, I almost have it done now.Maybe, it would be good to start another thread or continue this one about control of mass on a spring. Objective would be to try to find best response using PI only controller and then PID and to discuss about contribution of the derivative component.

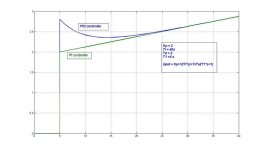

We could start by simple model Gp = 1/(s^2+0.2s+1), where damping ratio is much lower than 1. Some specifications can be stated like overshoot less than 20% and/or settling time less than 10sec or something like that.

It would be interesting to see and compare PI and PID solving this problem.

Anybody interested?

hi m doing my FYP regarding PID control of inverted pendulum.m facing problems now of having analoge interface with AB SLC 5/03.can u help me?if u can plz come online at yahoo [email protected] online here right nowHello,

I prefer using PD controller in level loops. The biggest strength of PD controller is in case if you're controlling level in some tank with motorized control valve. In that case, you'll have double integrator in the loop and problems with overshoot. PD can be used succesfully to provide good response.

I suggest you reading posted links ablut D part of the PID controller. If PV doesn't contain noise (properly filtered), then D can be your friend.

Like I said, I'm using D almost exclusively in level control(integrating process) and the structure really depends on actual application.

Regards,

Pandiani