I am not offended

It is the general statements made right after I made my post about the general statements made in the Control Engineering magazine. I am thinking why bother if people don't understand that each system is different.

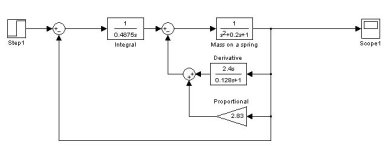

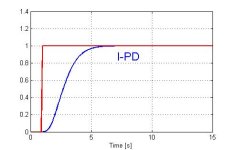

I have stumped many with the mass on a spring example. It may not be fair and I know that most of you don't tune a system that looks like a mass on a spring but still one must be careful when giving advice that you know what their system is and what form of PID they are using.

Bill Wheeler said:

PID control spanning a broad cross section of applications. I think that what I stated has merit for many

Yes, but what about those where your advice doesn't apply and may be harmful?

You are right that the compressed spring has potential energy but the energy is transfer to the mass and the spring at the same time. The force that compresses the spring also pushes and accelerates the mass. Also the potential energy in the spring only returns to zero when the spring is returns to its uncompressed or stretched state. It has nothing to do with friction. The energy in a spring is (k*x^2)/2 assuming spring constant k truly a constant. I don't see a friction term in there. If you think about it the more friction the more force that is required to overcome the friction so the spring compresses more and has more potential energy.

The D-term application applies also to any mechanical motion systems where the inertia (amount of resistance of a mass to a change in its velocity) can result in a significant error, and also applies to heating applications where a heating element represents a large thermal mass that continues to dissipate heat after power to the element is removed (Latent Heat). In broad terms I would say that “system inertia” is a fitting term that can be used to encompass all three of these conditions.

Another general statement to which I can find a simple exception.

A simple motor system with a time constant for the inertia K/(tau*s+1) does not need a derivative gain for velocity control. It doesn't matter how big the inertia is. The system may need power but not a derivative gain.

However for position control a derivative gain is required because the open loop system how has an extra pole for integrating velocity to position.

I’ve seen too many control issues resulting from the D-Term being applied for no other reasons than that it was there or the D-Term was used to compensate for too high I and/or P values.

That is a good enough reason if the error needs to be reduced by using higher gains.

I select P-Only when the PV response to a CV change is close to a linear function over the entire normal process range, and the measured PV response to the full CV change is very quick. An example where P-Only control works is flow control of a non-compressible fluid where the control valve’s CV coefficient is nearly linear from closed to fully open (i.e. v-ball design).

This is off topic but flow is proportional to the square root of the pressure drop so unless the pressure drop across the valve is constant.

P only gains don't work well unless the system is a type 1 or integrating system. There is always going to be an error while the SP is different from ambient or steady state for type 0 or non-integrating systems.

I select PI control when the control system “inertia” is smaller than the allowable SP overshoot; the process requires a fast response to a SP/PV error; and the process is tolerant to a repeatable level of SP overshoot. An example would be in-line heating application for a gas or liquid where the goal is to heat a fluid stream as quickly as possible and where a level of SP overshoot has negligible impact on the end product.

]

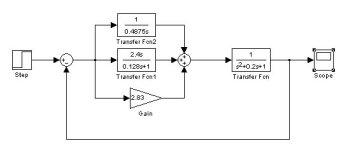

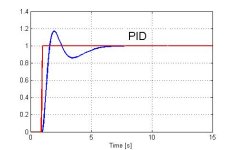

What about for a SOPDT system? A SOPDT system should have a derivative gain. A SOPDT system has one more pole than a FOPDT system and there should have one more gain. The system may tune OK without the derivative gain but the response will not be optimal.

I select PID control when the process goal is to minimize the recovery time of a SP error while also minimizing the SP overshoot resulting from system inertia or latent energy. An example would be an oven application where the desired goal is to recover to set point as quickly as possible while minimizing the overshoot caused by latent heat at the heating source.

It depends upon the number of poles in the open loop system, not whether it overshoots. I have said this before above.

Again I apologize if I have offended you – I just thought I would pop in and share.

I am not offended, I am just pointing out that you should know more about control theory, more about the other persons system and the form of PID they are using before offering advise. I believe you can get your systems going well enough. You need to know how different types of systems are tuned. There are type 0 ( non integrating ), type 1 ( integrating ). For both of these categories there are single pole or first order system and two pole ( second order systems ). The second order systems can be over damped, critically damped or under damped. Then you can add dead time to the mix for some systems. There are third order and higher systems. These can be nightmare systems to tune. You have to know what you are dealing with before giving advice.