I am experiencing an increasing temperature on one, or two, or even 3 of my load thermocouples in a high heat vacuum furnace. Normally, this is desired behavior except it is happening when the furnace switches to its quench (plunge cool) segment.

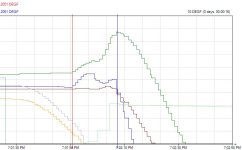

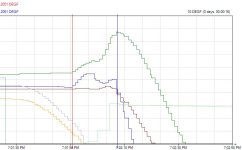

In the trend you can see the temperature reading rapidly increase for 16 to 18s before it peaks and begins decreasing as expected. The increase seems to be initially triggered by the backfilling of Argon, which begins at the red cursor. This is triggered by the opening of a pneumatic solenoid valve. Five seconds after the valve opens, a cooling blower spools up which is shown as the cooling blower amps in lime green. To note: the argon is room temperature up to the inlet.

To summarize the problem, a 2050F furnace under is backfilled with room temperature gas and the Load TC temperature increases, but the control thermocouples decrease as expected.

This particular order/part/recipe has some sort of spike ~85% of the time, while the others probably less than 5%.

The first thought was noise of some sort so we tried a few different things:

1) Grounded the TC to the load by soldering a short pigtail to the hot junction that made contact with the load.

2) Used an AB TC signal conditioner

3) 100mcF capacitor between TC(+) and TC(-) and jumped TC(-) to GND at the PLC.

All three were done alongside the load TCs and nothing showed positive results.

Having thought about it more, I have a hard time believing it is noise causing the issue because the temperature reading never has an exaggerated decrease and the duration of the increase is too long. This issue only occurs with this order, independent of furnace.

With that said, I do not have any other good explanations. Any other ideas would be much appreciated.

Other information:

PLC - HC900 via AI card

Type K TC

Trend Legend:

Green, Blue, Brown - Load TCs

Silver, Gold - Control TCs

Lime Green - Cooling Blow Amps

In the trend you can see the temperature reading rapidly increase for 16 to 18s before it peaks and begins decreasing as expected. The increase seems to be initially triggered by the backfilling of Argon, which begins at the red cursor. This is triggered by the opening of a pneumatic solenoid valve. Five seconds after the valve opens, a cooling blower spools up which is shown as the cooling blower amps in lime green. To note: the argon is room temperature up to the inlet.

To summarize the problem, a 2050F furnace under is backfilled with room temperature gas and the Load TC temperature increases, but the control thermocouples decrease as expected.

This particular order/part/recipe has some sort of spike ~85% of the time, while the others probably less than 5%.

The first thought was noise of some sort so we tried a few different things:

1) Grounded the TC to the load by soldering a short pigtail to the hot junction that made contact with the load.

2) Used an AB TC signal conditioner

3) 100mcF capacitor between TC(+) and TC(-) and jumped TC(-) to GND at the PLC.

All three were done alongside the load TCs and nothing showed positive results.

Having thought about it more, I have a hard time believing it is noise causing the issue because the temperature reading never has an exaggerated decrease and the duration of the increase is too long. This issue only occurs with this order, independent of furnace.

With that said, I do not have any other good explanations. Any other ideas would be much appreciated.

Other information:

PLC - HC900 via AI card

Type K TC

Trend Legend:

Green, Blue, Brown - Load TCs

Silver, Gold - Control TCs

Lime Green - Cooling Blow Amps