This technote has some good information regarding the filter settings for the 5069-IB16 inputs, as well as an interesting mention of a specific firmware upgrade which changes the way this module's filtering handles potential noise induced false signals...

1046736 - 5069-IB16 Inputs not Detecting Signals as Expected

Access Level: TechConnect

To use the embedded High Speed Counters open the Module Properties for the 5069-IB16 input module. This can be done by double-clicking on the input module instance under the I/O Configuration in your Logix 5000 project. Under the General category, open the Module Definition by clicking on the "Change" button. Here, under "Counters", you must first select away from "None" to at least "2" counters (2, 4, 8 may be selected).

OK the change and back at the previous screen you should now see the "Counters" category has been added. If you enter this category you will now see the settings for the number of counters you have enabled.

Note: When you enable counters in pairs (2, 4, 8), they will be using some of the available 16 input points for their signals, starting at point 0. For instance, if you enable 2 counters, then input points 0 and 1 are reserved for counter 0 and 1 functions, and so on up to point 7 (0-7 for maximum 8 counters enabled). When a counter has reserved an input point, the input filtering to be applied is adjusted under the Counters category, and not under the "Points" category.

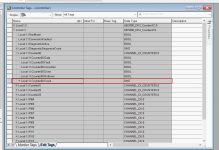

Once counters have been enabled, and the Counters category created, the module-defined data type for the module will change to reflect the new Counter I/O tags. You can view these under Controller Tags, within the Configuration, Input, and Output tags for the module. You may use these tags to incorporate the counter(s) into your application.

Regards,

George