Bullzi

OK, so here's the scoop. This is working well for us when I did a bunch of air handlers for a new office building/lab at Ford the last 2 years. I wrote all these programs from scratch, BTW. So you may think something is weird, but everyone programs differently.

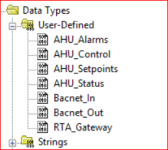

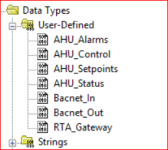

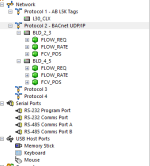

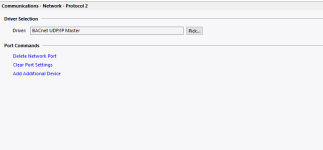

The snip shows UDT's which will be as follows: Bacnet_in is AHU control and AHU setpoints, Bacnet_out is AHU alarms and AHU status. So those AHU UDT's are nested in Bacnet in and Bacnet out. Bacnet "in" means an operation from either BAS or the operator OR from the HMI will go through the BACnet software in the JACE controller and then into the gateway and into logic. BACnet "out" is reversed. A readback, for instance, from a setpoint would go the other way and show up in the HMI at the unit or the operator console at BAS. Lastly, the RTA gateway is where the real template comes in. Those gateways are like anything else, the tags have to match exactly or it won't send or receive a value and just throw an error for that point. The first few units I did in '18 I had the PLC tags in the gateway, and had a lot of problems with this--syntax, data type etc. So my boss invented this template for these last 3 units.

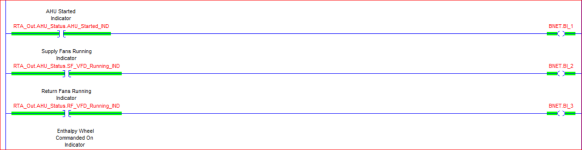

So the way this works is your BACnet integrator will assign points to his program. An example in the snip is Outside air temp. It comes into BACnet from the BAS. He assigned it to a point in his program, which is irrelevant to me. I then had him assign that point to BNET.AO_44, which is in the RTA Gateway UDT. He can see this. His system doesn't care what my tag name is, only what point I want it assigned to in the gateway. Now I took that gateway tag, BNET.AO_44 and used it in logic, for which now I can assign that analog value of Outside air temp anywhere in logic. So the BACnet out is going into the gateway (RTA_in.AHU_Control.Outside_Air_Temp.) and I moved it to a tag which I use in logic. Actually OAT is important for heating and cooling mode changes/permissives.

So then, an AI would be like supply air temp which comes into my PLC from a sensor in the unit to an AI card in the rack. I send that value up the "chain" as I described above in reverse to the gateway, JACE, HMI and BAS console/operator so they can see it. Hope this helps you, let me know if I can be of further confusion--I mean assistance. Stay healthy and safe.