memphiskt007

Member

Hello,

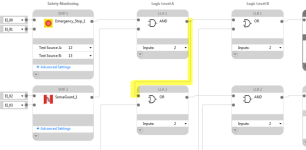

Does anyone have any experience with Rockwell's Guardmaster 440-CR30 safety relays? As I understand it, you need to use Connected Components Workbench to program these devices. Everything I have read indicates you have 2 "Logic Levels" to program with. This seems like a fairly serious limitation. If you have experience with CCW, some design insight might be helpful here.

Does anyone have any experience with Rockwell's Guardmaster 440-CR30 safety relays? As I understand it, you need to use Connected Components Workbench to program these devices. Everything I have read indicates you have 2 "Logic Levels" to program with. This seems like a fairly serious limitation. If you have experience with CCW, some design insight might be helpful here.