>I think it will be 70RPM which will have a cycle of 285.71ms/pulse.

Let's first make sure we understand the signal generator.

If you have three equal-sized segments of a rotating "flag" being sensed by an inductive or optical sensor on a shaft turning 70 RPM, then the signal will be ON for 0.1428 seconds and OFF for 0.1428 seconds.

If you instead have three small "flags", then the pulses are shorter, but could be as much as 280-or-so milliseconds apart.

>And the frequency of the plc input is 8 ms.

It sounds like you're describing a filter value on the DC inputs of the Micro 820. 8 ms is the default filter on a DC input on the Micro 820 (and on most PLCs), and is used to reject induced noise from AC cables and loads in the electrical environment. One of our Forum members has a

good video tutorial on the subject on YouTube. Right at the 1:35 mark, he shows that the Micro 820 can have that filter disabled by setting it for 0 ms.

The Micro 820 does not have all of the features of the Micro 830, 850, and 870 controllers. That includes built-in High Speed Counter features, and built-in High Speed Interrupts in hardware, which would be required for high frequencies in the kHz ranges.

It does have the ability to host a High Speed Counter "plug in" module, the 2080-MOT-HSC.

>on the micro820 I don't have the clockbits

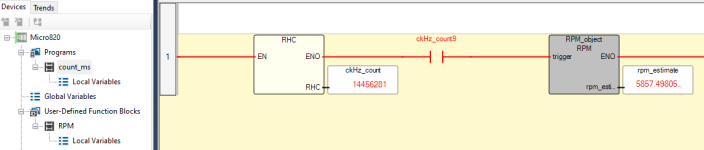

All of the Micro 800 controllers have a "high speed clock" that is accessed using the RHS instruction. On the Micro 820, that clock increments by 1 every 10 microseconds. That is what our friend drbitboy has illustrated in detail in his posts.

And to my knowledge, all of the Micro 800 controllers do support Event Interrupts (EII). I have used input event interrupts to capture free-running clocks in order to calculate speed or frequency on other controller platforms, but not on the Micro 820.

But before we discuss other options, I think you should understand and describe the device that is generating the pulses to measure the shaft speed of your machine, so you know the actual timing performance your controller needs to provide.