Hi all,

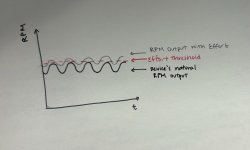

I am working on a project that needs to detect when a user is putting in effort into the system (this is a robotic gait trainer that functions similar to a elliptical). I am looking at the RPM of the motor to determine this. When the user inputs effort, an increase in RPM can momentarily be seen while effort is being exerted, and the HMI indicates that effort was made live.

Due to the system's linkage design, the RPM fluctuates through a range based on the users speed and step length (e.g. The motor is set to run at 25 rpm, but live readout of the RPM will be 22-27. When effort is exerted, you can see the the range shift to be 25-30).

Right now, my logic will scan motor for a 5 seconds, pull what the max RPM value is, and use that at the reference against the live read out, so in my example, if the RPM exceeds 27, the user has put in effort). However I want to try to make it more sensitive. For the RPM values that overlap in the NoEffort and Effort RPM ranges, is there anyway to differentiate between the effort vs. non-effort? I attached a rough sketch of what my HMI trend lines look like for each scenario. Thank you!

I am working on a project that needs to detect when a user is putting in effort into the system (this is a robotic gait trainer that functions similar to a elliptical). I am looking at the RPM of the motor to determine this. When the user inputs effort, an increase in RPM can momentarily be seen while effort is being exerted, and the HMI indicates that effort was made live.

Due to the system's linkage design, the RPM fluctuates through a range based on the users speed and step length (e.g. The motor is set to run at 25 rpm, but live readout of the RPM will be 22-27. When effort is exerted, you can see the the range shift to be 25-30).

Right now, my logic will scan motor for a 5 seconds, pull what the max RPM value is, and use that at the reference against the live read out, so in my example, if the RPM exceeds 27, the user has put in effort). However I want to try to make it more sensitive. For the RPM values that overlap in the NoEffort and Effort RPM ranges, is there anyway to differentiate between the effort vs. non-effort? I attached a rough sketch of what my HMI trend lines look like for each scenario. Thank you!